Are corn flakes made from mold?

Are corn flakes made from molds?

How are corn flakes made?

Corn flakes are a very popular breakfast cereal that many people like very much. They are easy to consume, as they can be eaten immediately with milk, making them the perfect breakfast cereal for people in a hurry.

I believe we can all find that the cornflakes we usually buy have many different shapes, but the shape of the same cornflakes is the same, which makes people very curious, whether the cornflakes are made using a mold to make such a uniform shape?

Are corn flakes made from mold?

Corn flakes are a breakfast cereal made with corn as the main ingredient and added with sugar, salt, and additives such as vitamins and minerals. It is prevalent in modern society.

Nowadays, the improvement of the economic level makes consumers have higher requirements for corn flakes, and manufacturers can only meet the needs of consumers by continuously improving the production process. The highly automated production method can ensure the quality and efficiency of cornflake production, and manufacturers will use different molds to produce different shapes of corn flakes.

Each bag of corn flakes has the same shape, mainly because the molds of the equipment are the same. In order to be able to provide consumers with more fresh styles, manufacturers will customize different molds, such as triangular, round and square, etc. The mechanized production method can ensure the uniformity of the corn flakes, which look higher quality.

How are corn flakes made?

1. Ingredients: The ingredients of cornflakes are crucial. Only by choosing the right kind of corn, then adding sugar, salt, and some other nutrients, and blending them according to the standard recipe can we ensure that the cornflakes have a better taste.

2. Extrusion ripening molding: This is the most critical step in the production of corn flakes. Only when the corn flakes are matured without any puffing can the produced corn flakes be crisp and attractive.

3. Cutting: The cooked material is cut into corn flakes of uniform size, and the corn flakes in this state are translucent.

4. pre-drying: cutting and forming the corn flakes need to be pre-drying treatment to facilitate the subsequent processing and not cause the corn flakes to stick together.

5. Pressing: The pressing machine can press the corn flakes to the required thickness, making them more crispy to eat.

6. High-temperature baking: After drying at high temperatures, the corn flakes are crispier to eat, richer in taste, and more compact in the organization.

7. Seasoning: This step is optional, as consumers are now more demanding, so the appropriate seasoning will be more conducive to attract consumers.

8. packaging: packaging machine for packaging, packaging can effectively extend the shelf life of corn flakes and improve the grade of corn flakes.

The above is the specific production process of corn flakes. As long as the shape of the mold can be changed to produce different shapes of corn flakes, there are various shapes available for manufacturers to choose from.

In this very competitive environment, efficiency is life, and manufacturers can only stand out in the cornflake industry if they can produce high-quality cornflakes quickly and efficiently. The choice of quality production equipment has become the key. After all, in the era of mechanized production, high-performance equipment represents a broader market.

In this very competitive environment, efficiency is life, and manufacturers can only stand out in the cornflake industry if they can produce high-quality cornflakes quickly and efficiently. The choice of quality production equipment has become the key. After all, in the era of mechanized production, high-performance equipment represents a broader market.

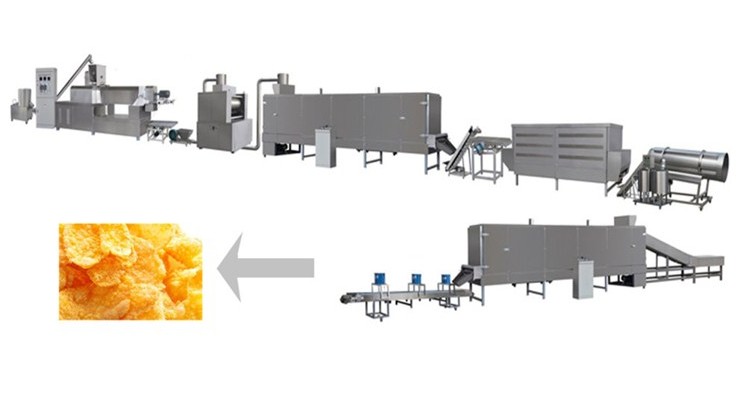

Corn Flake Production Line is a new type of machinery developed by our engineers after many experiments, with superior performance. The line combines the most advanced production experience at home and abroad, and also listens to the suggestions of many famous cornflake companies, making the line one of the most suitable equipments for manufacturers' actual production needs.

The Corn Flake Production Line is highly automated and equipped with a PLC control system, making it very easy to operate and produce many types of breakfast cereals. In addition, we can customize the molds according to the manufacturer's requirements, so no matter what shape of cornflake you want to produce, we can make it happen for you.

If you also want to buy a high-quality machine so that your production can achieve a qualitative leap, welcome to contact us. We will provide you with the most satisfactory service!