Uncovering the secrets of pet food production line technology

A new pet food production line has been successfully developed to adapt to the growing pet food market. This pet food making machine gives pet food novel shapes, flavors and colors, and meets the needs of the modern pet food market with scientific nutritional ratios and easy digestion.

As the core process of modern pet feed production, puffing technology has become the mainstream method of pet dry food manufacturing with its advantages such as high efficiency, complete nutrition retention and diverse product forms.

Moreover, the history of puffed pet feed can be traced back to the mid-20th century. Its development was accompanied by technological innovation in the pet food industry and people's in-depth understanding of pet nutritional needs.

The following are the key development stages

1. Early pet food (late 19th century-early 20th century)

(1) Primitive form: Early pets (mainly dogs and cats) fed on leftover food or raw meat from human tables and lacked special formulas.

(2) The beginning of commercialization: In the 1860s, British businessman James Spratt launched the first dog biscuit (made from a mixture of wheat, vegetables and blood), marking the birth of commercial pet food.

2. The rise of canned food (1920-1940s)

In the 1920s, the United States began to produce canned wet food (such as Ken-L Ration), which became popular due to its good palatability, but was expensive and inconvenient to store.

- Breakthrough in puffing technology (1950s-1960s)

(1) Key invention: In 1957, Purina (now Nestle Purina) in the United States first applied puffing technology to dog food production and launched the first puffed dry food Purina Dog Chow.

Technical principle: By extruding raw materials (grains, meat, etc.) under high temperature and high pressure, the pressure is released instantly to expand the particles, forming a porous structure that is easy to digest and has a long shelf life.

Advantages: Low cost, convenient storage, balanced nutrition, and quickly became mainstream.

- Scientification (1970s-1990s)

Nutrition research: With the development of pet nutrition, puffed feed began to add vitamins, minerals and specific nutrients (such as taurine, which is essential for cats).

- High-end and diversified (21st century to present)

(1) Segmented market: Special puffed food for age, breed, and health problems (such as weight loss and urinary health) has emerged.

(2) Natural and functional: Consumers prefer products without additives and with high meat content, and innovative forms such as freeze-dried puffed mixed food have emerged.

(3) Sustainability: Attempts to use environmentally friendly raw materials such as plant protein and insect protein.

6. The core impact of puffing technology

(1) Sterilization and preservation: High temperature treatment kills pathogens and extends shelf life.

(2) Nutritional balance: Various ingredients can be accurately formulated to meet the complete nutritional needs of pets.

(3) Palatability: The texture after puffing is more acceptable to pets.

Overview of puffing technology

1. Basic principles of puffing process

Puffing is a process in which the material undergoes physical and chemical changes in a short period of time through the combined action of high temperature, high pressure and shear force. When the pressurized hot material is extruded from the die head to the normal pressure environment, the water vaporizes instantly, causing the material volume to expand and form a porous structure.

2. Advantages of pet feed puffing

(1) Improve digestibility: starch gelatinization can reach 85-95%

(2) Sterilization effect: high temperature process can eliminate most pathogenic microorganisms

(3) Diverse shapes: particles of different shapes can be produced by changing the mold

(4) Good palatability: Maillard reaction produces appetizing flavor substances

(5) Extend shelf life: low moisture content inhibits microbial growth

Pet feed production by puffing machine is a comprehensive technology that integrates food science, mechanical engineering and animal nutrition. As the demand for high-quality products in the pet food market grows, the puffing process will continue to innovate and upgrade.

Today, puffed feed occupies a major share of the global pet dry food market. Its development reflects the leap from "fullness" to "scientific nutrition". In the future, it may further integrate biotechnology and personalized customization trends. In the future, personalized customization, functional enhancement and sustainable production will become the main directions of the development of puffed pet feed technology.

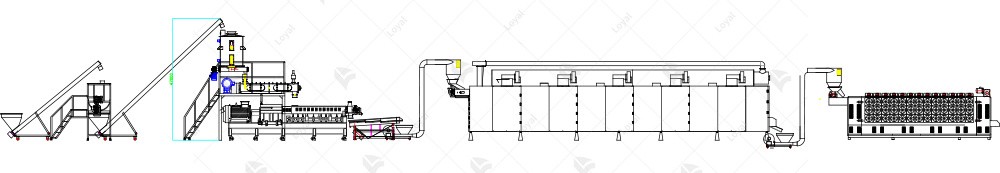

Pet food production line flow chart

1.Mixer ---2.Screw conveyor ---3.Twin-screw extruder ---4.Air Conveyor ---5.Oven ---6.Hoister ---7.Flavoring machine --- 8.Cooling Machine

The pet food making machine completes the whole process from batching, extrusion, puffing, drying, seasoning to finished products at one time, which is fully automated.

The function of pet food equipment

- Mixer: Mixer makes the raw material adding to water and other chemical additive fully mixed.

- Screw Conveyor: Screw conveyor is advantage is suit for powder item that is bad fluidity. In food processing industry, it is for conveying flour, powder additives, seasoning powder ect. Here is used to elevate the mixed raw materials to extruder.

- Twin Screw Extruder: Extruding different shapes by placing different molds. The screw has a self-cleaning function, and there is no need to disassemble the screw for cleaning when the machine is stopped

- Air Conveyor: Used to carry products to the next machine.

- Oven: This machine is used to dry the snacks food. The heating temperature and the drying speed can be adjust. It can be used to bake and dry the food. The oven can bake all kinds of the inflating food, pet food, TVP/TSP food, peanut, nut, chew nut and so on. The temperature can be controlled willfully and designed according to the need.

- Hoister: elevate products to flavoring machine

Flavoring Machine: Spray seasoning oil and powder onto the snacks so as to make the snacks tasteful.It can mix liquid, such as oil, honey, syrup, with snack food, beans, peanuts, chips, teas and other food.

- Cooling Machine: Cooling the product easy to pack or store.

Technical specifications of pet food making machine

|

Model |

Installed power |

Power consumption |

Output |

Size(L*W*H)(mm) |

|

LY65 |

70kw |

45kw |

120-150kg/h |

20000*1200*2200 |

|

LY70 |

105kw |

85kw |

200-250kg/h |

22000*1500*2200 |

|

LY85 |

160kw |

130kw |

300-500kg/h |

25000*2500*2300 |

|

LY95 |

220kw |

154kw |

800-1000kg/h |

28000*2500*3500 |

|

KING135 |

241.2kw |

180.9kw |

1500-2000kg/h |

45000*2000*3000 |

|

Heating Source |

Electricity Or Gas Or Diesel Or Steam |

|

Voltage |

Three phase 380V 50HZ (can customized) |

|

Standard |

The Motor Can Choose Siemens, Delixi Or Delta Combine With Good Brand Electrcity Parts |

|

Machine materials |

Contact food SS 304, Frame: carbon steel Screw of extruder: 38CrMoAi Cutter and dies: carbon steel Barrel: 45# steel/A101 alloy |

Layout for the pet food making machine

Our machines can be flexibly arranged according to the size and dimensions of the factory. Our machines can be arranged not only in a straight line, but also in a curved arrangement. We can also customize the size of the machine according to the data you provide.

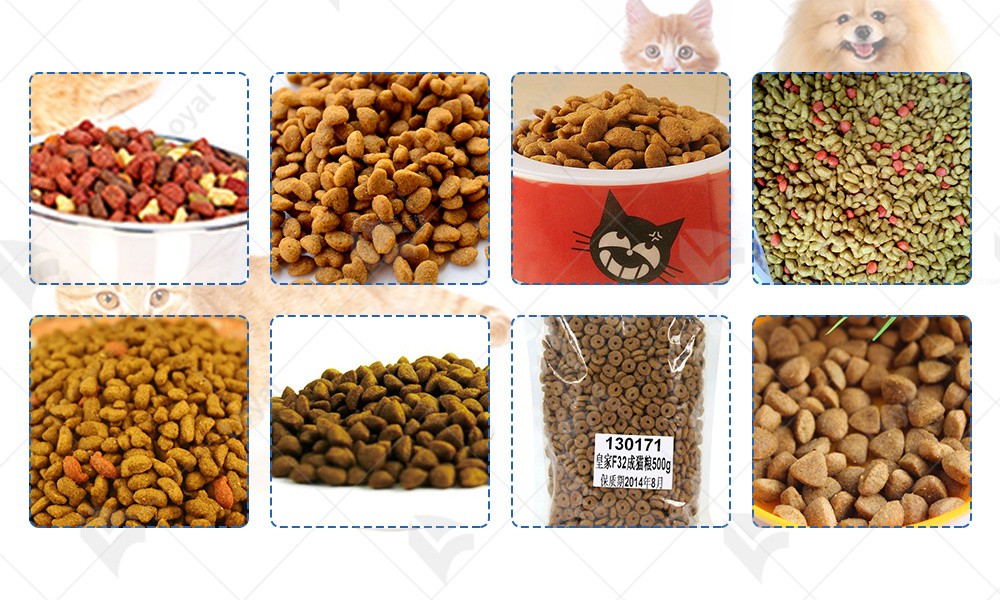

Sample of pet food making machine

Extruding different shapes by placing different molds.

What are the advantages of pet food manufacturing process?

1. Twin-screw extruders can not only make pet food, but also produce other types of food.

2. Our machines use advanced frequency conversion control technology, which greatly reduces electricity and labor consumption.

3. We have famous partners such as Siemens.

4. Our machine materials are food-grade stainless steel, carbon steel, etc.

5. The control system of the twin screw extruder has three frequency converters, and the speed of rotary cutting, screw speed and feeding speed can be adjusted. It can save energy, adjust speed, protect, improve process level and quality, and extend the service life of equipment. The power of the motor can be adjusted by converting the power supply frequency, and the motor can be operated at a variable speed.

What other production lines can it be used on?

1. The production line can heat and extrude raw materials, and press pet food of different shapes through molds to meet the tastes of different pets.

2. Pet food production lines can be widely used to produce dog food, cat food, bird feed and fish feed.

3. Twin-screw extruder is used in many food production lines, such as extruded snacks, corn flakes, breakfast cereals, sandwich rice crackers and nutritional powder.

4. However, it should be noted that the fishy smell of bone meal in pet food raw materials is very strong. If it is made into extruded food for human consumption after making feed, it may have a cross-flavor and affect the taste.

About packaging and after-sales service

Packing: Plastic Film Suitable For Ocean Carriage

Technical Support: The customer can inform machine related problems to us via telephone, email or fax. All information will be recorded and will be reported to the After-sale Service team. Meanwhile, the sales person will be tracking the case until problem solved.

Service Team:We have a professional After-sale Service team including10 professional engineers with at least 6 years working experience. They can handle technical consultation about manufacturing process, maintenance, fault diagnosis and troubleshooting, etc.

After-sale Service available :1.Check & test before delivery 2.Instruction for installation 3.On site commissioning 4.Repair & maintenance

After the receipt the advanced payment, we will provide allocation chart at the buyer’s request. When effect the shipment, we’ll provide operation manual, etc. in English.

Recommended Company

Shandong Loyal Industrial Co.,Ltd. Is a Manufacturer Of Snacks Extruder Machine , Industrial Microwave Oven , Corn Flakes Production Line , And a Standing Director Of China Food And Drying Equipment Industry Association.

The Self-developed Twin-screw Extruder And Single-screw Equipment of Shandong Loyal Machinery Have Been Used In Production: Puffed Snack Food, Breakfast Cereal Corn Flakes, Fried Pasta, Bread Crumbs, Fruit Chips, Baby Food, Textured Soy Protein (tsp) Food, Fish Feed And Pet Food. a Variety of Snack Production Line Supporting Products.at The Same Time, The Batching, Drying, Flaking, Baking, Frying And Spraying Equipment Matching The Twin-screw Extrusion System Have All Achieved Independent Design And Production.

Our Extrusion System Is Widely Used In: Puffed Snack Foods, Breakfast Cereals, Vegetable Protein Meat Products, Soy Based Nutrition Bars, Reconstituted Rice, Grain Nutrition Powder, Modified Starch, Starch-based Sticky Music Children's Educational Toys, Degradable Starch-based Packaging Filling Materials, Bread Crumbs And Other Food Additives, Pet Food, Aquatic Feed, Biology And Chemical Industries.

Customer-specific Food Processing Plant Project Solutions

As one of the leading manufacturers of food processing equipment, we are always searching for new solutions that benefit our snack food customers. Our experienced frying engineers always find the optimal solution for your industrial batch and continuous frying system line application. That's why we also develop, design and produce custom fried snack production line.

Close collaboration with our customer is important to us even in the early development phase. No matter what the special requirements of instant noodles production line, snack food extruder machine, pasta production line application, we can develop a custom made food processing equipment to match your needs.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

Loyal Food Production Line meet the needs of customers to obtain snack food that meet the needs.

In ovens or drying units, electric or gas can be used as heating sources.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

Choosing the right pet food is an important responsibility of responsible pet owners. By understanding your pet's specific needs, reading labels carefully, and communicating with your veterinarian, you can provide your pet with the best nutritional support and enjoy a longer healthy companionship together.

Remember: there is no "best" pet food, only the "most suitable" pet food. Observing your pet's reaction to food, regularly evaluating its physical condition, and adjusting the diet according to its life stage is the core of scientific feeding.