Explore The Process Flow Of The Fully Automatic Pet Dry Food Machine

With the development of social economy, more and more people keep pet, and the demand for pet food is also increasing. Pet food production lines have been developed and widely used. Depending on the output, dry pet food processing line equipment also have a variety of models and configurations. The production line mainly uses meat meal, fish meal, bone meal, corn meal, soybean meal and other grain powder as the main raw materials. By adjusting the raw materials, temperature, humidity and other process parameters, it produces novel-shaped, nutritious and delicious pet food. The production line can be widely used in the production of feed for pets such as dogs and cats, as well as aquatic feed for animals such as fish and shrimp.

Description of Fully Automatic Dry Pet Food Machine

|

No. |

Item |

Detail descriptions |

|

1 |

Raw materials |

Meat meal, fish meal, bone powder, corn powder, soya meal and other grains’ powder, etc. |

|

2 |

Consumption |

Low energy consumption, low labor |

|

3 |

Capacity |

120-150kg/h, 200-250kg/h, 300-500kg/h, 800-1000kg/h,1500-2000kg/h |

|

4 |

Machine material |

Stainless steel |

|

5 |

Products |

This Dry Pet Food Processing Line Equipment can produce pet food with various flavors. By adjusting the parameters, the raw materials can be extruded into various shapes through the mould. |

Technical Parameter of the Professional Pet Food Processing Equipment

|

Model |

Power Consumption |

Output |

Dimension |

|

LY 65 |

45kw |

120-150kg/h |

20000*1200*2200mm |

|

LY 70 |

85kw |

200-250kg/h |

22000*1500*2200mm |

|

LY 85 |

130kw |

300-500kg/h |

25000*2500*2300mm |

|

LY 95 |

154kw |

800-1000kg/h |

28000*2500*3500mm |

|

KING135 |

180.9kw |

1500-2000kg/h |

45000*2000*3000mm |

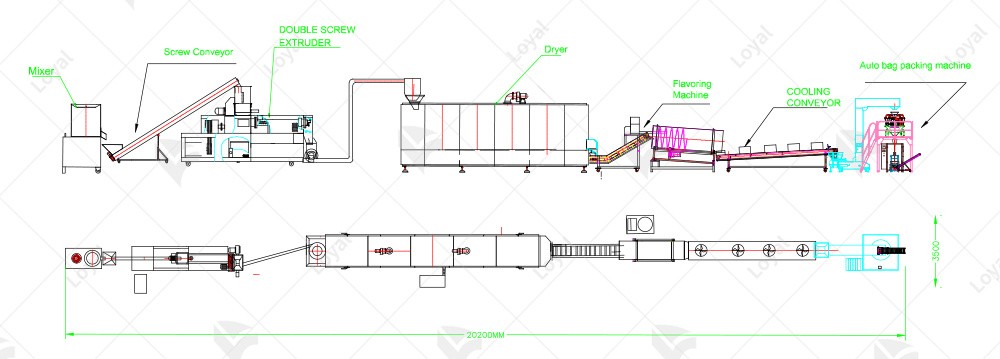

Layout for the Dry Pet Food Processing Line Equipment

①Flour Mixer→②Screw Conveyor→③Double Screw Extruder→④Air Conveyor→⑤Dryer→⑥Flavoring Machine→⑦Cooling Machine

Our machines can place flexibly according to the size and the dimension of factory. Our machines can be placed not only straight but also bent.

Working Process of Efficient Dry Pet Food Processing Line Equipment

1. Flour mixer: mix raw materials

2. Screw conveyor: convey raw materials

3. Twin screw extruder: expand raw materials and extrude different shapes of food by placing different molds

4. Air conveyor: convey light and small raw materials

5. Oven: remove moisture and extend shelf life

6. Seasoning machine: spray seasoning oil and seasoning powder evenly on food

7. Cooler: cool for subsequent packaging

What Is The Advantages Of The Pet Food Manufacturing Process?

1. We have different types of machines to meet the production needs of different foods.

2. Our machines use advanced variable frequency speed regulation technology, which greatly reduces the consumption of electricity and labor.

3. We have well-known partners such as Siemens for fine electrical equipment.

4. Our machine materials include food-grade stainless steel SS304 and SS201, which ensures food safety and durability.

5. Our feeding system, extrusion system and cutting system all use frequency converter speed regulation, which is simple and convenient to operate.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/