The Ultimate Guide to Automatic Biscuit Making Machine in 2024

Introduction

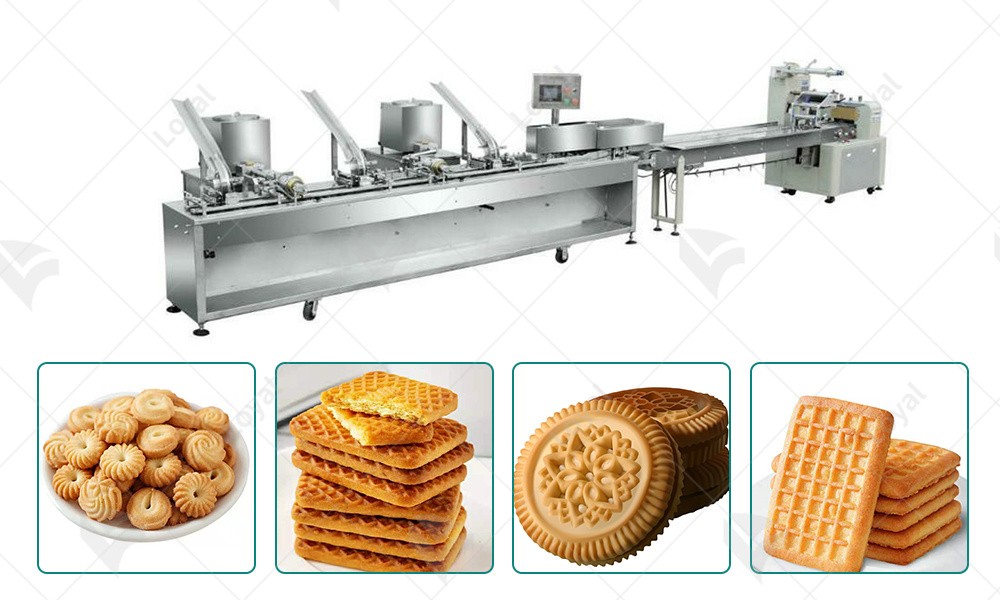

Overview of Automatic Biscuit Making Machines

Automatic biscuit making machines have revolutionized the baking industry by enhancing efficiency, consistency, and production capacity. These machines are designed to automate the entire biscuit production process, from mixing ingredients to baking and packaging. The use of an automatic biscuit making machine ensures uniform quality and reduces the need for manual labor, which is particularly beneficial for large-scale production.

Importance and Benefits in Modern Baking Industry

The significance of automatic biscuit making machines in the modern baking industry cannot be overstated. They offer several benefits, including increased production speed, reduced labor costs, and improved product consistency. Furthermore, these machines can handle various biscuit types and shapes, catering to diverse consumer preferences. By automating repetitive tasks, bakeries can focus on innovation and quality improvement, thereby maintaining a competitive edge in the market.

Evolution and Trends Leading up to 2024

The evolution of automatic biscuit making machines has been marked by significant technological advancements. Early machines were simple and limited in functionality, but today's models are highly sophisticated, featuring programmable logic controllers (PLCs), advanced sensors, and integration with other smart devices. Trends leading up to 2024 indicate a growing emphasis on sustainability and energy efficiency. Modern machines are designed to minimize waste and optimize resource use, aligning with global environmental goals. Additionally, the incorporation of AI and machine learning is expected to further enhance the precision and efficiency of biscuit production.

Basic Components

An automatic biscuit making machine is composed of several critical components, each playing a vital role in the seamless production of high-quality biscuits. Understanding these components is essential for anyone looking to invest in or operate these machines efficiently.

Key Components and Features

1. Mixer: The mixer is responsible for combining ingredients into a homogeneous dough. It ensures that the dough has the right consistency and texture, which is crucial for producing uniform biscuits. Modern mixers are equipped with programmable settings to handle different recipes and ingredient proportions.

2. Dough Feeder: The dough feeder transfers the prepared dough from the mixer to the forming section. It ensures a continuous and controlled flow of dough, preventing any interruptions in the production process.

3. Forming Machine: This component shapes the dough into biscuits. The forming machine can be customized with different molds and rollers to produce various biscuit shapes and sizes. Advanced models use precision technology to ensure consistent shape and size with minimal waste.

4. Baking Oven: The baking oven is a critical component where the formed biscuits are baked to perfection. These ovens are designed to maintain uniform temperature and airflow, ensuring even baking. Modern ovens are highly energy-efficient and can be programmed for different baking profiles.

5. Cooling Conveyor: After baking, biscuits need to cool down before packaging. The cooling conveyor transports the hot biscuits through a controlled cooling environment, preventing any deformation or quality issues.

6. Packaging Machine: The final component is the packaging machine, which wraps the cooled biscuits into various packaging formats. This can include plastic wrapping, carton boxing, or any other preferred packaging method. Packaging machines ensure that the biscuits are protected from environmental factors and extend their shelf life.

Advanced Features

Automatic biscuit making machines in 2024 come with several advanced features to enhance productivity and quality:

Programmable Logic Controllers (PLCs): PLCs allow for precise control and automation of the entire biscuit-making process. Operators can easily adjust settings and monitor performance through user-friendly interfaces.

Sensors and Quality Control Systems: Integrated sensors monitor various parameters such as dough consistency, baking temperature, and moisture levels. These systems ensure that every biscuit meets the desired quality standards.

Energy Efficiency: Modern machines are designed to consume less energy, contributing to lower operational costs and reduced environmental impact.

Working Principle of the Automatic Biscuit Making Machine

The automatic biscuit making machine operates through a series of well-coordinated processes designed to ensure the efficient and consistent production of biscuits. Understanding the working principle of this machinery is essential for optimizing its use and maintaining high production standards.

How They Work: Step-by-Step Process

1. Ingredient Mixing: The process begins with the precise mixing of ingredients in the mixer. Ingredients such as flour, sugar, fats, and flavorings are combined into a uniform dough. The mixer ensures thorough blending to achieve the right consistency, which is crucial for the next stages.

2. Dough Feeding: Once the dough is prepared, it is transferred to the dough feeder. This component regulates the flow of dough into the forming machine, ensuring a steady and consistent supply.

3. Dough Forming: The dough is then fed into the forming machine, where it is shaped into biscuits. The machine uses various molds and rollers to create different shapes and sizes. Precision technology ensures that each biscuit is uniform in shape and size, which is essential for maintaining product quality.

4. Baking: The shaped dough pieces are conveyed into the baking oven. The oven's temperature and airflow are meticulously controlled to ensure even baking. This step is critical, as it determines the texture and color of the final product. Modern ovens in automatic biscuit making machines are designed for energy efficiency and consistent heat distribution.

5. Cooling: After baking, the hot biscuits are transferred onto a cooling conveyor. This stage allows the biscuits to cool gradually to room temperature, preventing any structural deformation and ensuring they are ready for packaging.

6. Packaging: The final step involves packaging the cooled biscuits. The packaging machine wraps the biscuits in appropriate packaging materials to protect them from moisture, contamination, and physical damage. Proper packaging extends the shelf life of the biscuits and maintains their quality during storage and transportation.

Automation and Control Systems

Modern automatic biscuit making machines are equipped with advanced automation and control systems. Programmable Logic Controllers (PLCs) manage the entire process, from mixing to packaging, allowing for precise control over each step. Sensors and quality control systems continuously monitor parameters such as dough consistency, baking temperature, and moisture content, ensuring that each batch of biscuits meets high-quality standards.

Types of Biscuit Making Machines

|

Type of Machine |

Key Features |

Applications |

Advantages |

|

Rotary Moulding Machine |

Uses rotary molds to shape dough into biscuits |

Ideal for producing soft and fancy-shaped biscuits |

High precision and variety in shapes |

|

Wire Cut Machine |

Cuts dough into uniform pieces using a wire mechanism |

Suitable for making cookies and shortbread biscuits |

Consistent size and shape, easy to adjust for different sizes |

|

Depositing Machine |

Deposits dough onto baking trays in specific shapes |

Perfect for cream-filled biscuits and decorative designs |

High accuracy in dough placement and design |

|

Tunnel Oven |

Continuous baking process with adjustable temperature zones |

Used for large-scale production of all types of biscuits |

Even baking and high throughput |

|

Hard Biscuit Production Line |

Integrated system for mixing, forming, baking, and cooling |

Best for producing hard and crispy biscuits |

Complete automation from dough preparation to packaging |

|

Soft Biscuit Production Line |

Specialized in handling softer dough for delicate biscuits |

Optimal for producing soft and chewy biscuits |

Gentle handling to maintain dough texture |

Key Features of Modern Automatic Biscuit Making Machines

Modern automatic biscuit making machines are designed with advanced features to enhance efficiency, consistency, and versatility in biscuit production. Understanding these key features is crucial for making informed decisions and optimizing your production process.

Key Components and Features

1. Programmable Logic Controllers (PLCs):

Automation: PLCs enable complete automation of the biscuit-making process, from mixing to packaging.

Precision: They allow for precise control over machine operations, ensuring consistency and quality.

User-Friendly Interfaces: Modern PLCs come with intuitive interfaces for easy programming and monitoring.

2. Advanced Mixing Technology:

Homogeneous Mixing: Ensures even distribution of ingredients for uniform dough consistency.

Variable Speed Control: Adjusts mixing speed to suit different recipes and dough types.

Energy Efficiency: Modern mixers are designed to consume less power, reducing operational costs.

3. High-Precision Dough Forming:

Customizable Molds and Rollers: Allows production of various biscuit shapes and sizes.

Consistency: Advanced forming technology ensures each biscuit is identical in shape and weight.

Minimal Waste: Precision forming reduces dough waste, optimizing resource use.

4. Energy-Efficient Baking Ovens:

Uniform Heat Distribution: Ensures even baking across all biscuits.

Temperature Control: Adjustable temperature settings for different baking profiles.

Energy Savings: Modern ovens are designed to be more energy-efficient, reducing overall production costs.

5. Integrated Quality Control Systems:

Real-Time Monitoring: Sensors continuously monitor dough consistency, baking temperature, and moisture levels.

Automatic Adjustments: The system can make real-time adjustments to maintain product quality.

Data Logging: Captures production data for analysis and continuous improvement.

6. Flexible Packaging Solutions:

Versatile Packaging Options: Capable of handling various packaging formats such as plastic wrapping, carton boxing, and more.

High Speed: Ensures rapid packaging to keep up with production rates.

Protection and Shelf Life: Ensures biscuits are well-protected from environmental factors, extending shelf life.

Benefits of Using Automatic Biscuit Making Machines

|

Benefit |

Description |

|

Increased Production Efficiency |

Automatic machines streamline the biscuit-making process, significantly reducing production time and increasing output. |

|

Consistency and Uniformity |

Ensures that each biscuit is identical in size, shape, and quality, meeting strict quality standards and reducing variations. |

|

Labor Cost Reduction |

Automation reduces the need for manual labor, lowering operational costs and minimizing human error. |

|

Enhanced Product Quality |

Precise control over mixing, forming, and baking processes results in superior product quality, with consistent taste and texture. |

|

Flexibility and Versatility |

Capable of producing a wide range of biscuit types and shapes, allowing for greater product diversity and market reach. |

|

Improved Hygiene and Safety |

Automated systems reduce human contact with the product, enhancing hygiene and compliance with food safety regulations. |

|

Energy Efficiency |

Modern machines are designed to be energy-efficient, reducing power consumption and lowering environmental impact. |

|

Scalability |

Easily scalable to accommodate increased production demands, supporting business growth and expansion. |

|

Data and Quality Control |

Integrated sensors and quality control systems provide real-time monitoring and adjustments, ensuring high-quality output and efficient troubleshooting. |

|

Reduced Waste |

Precision in dough handling and forming minimizes waste, optimizing resource use and lowering production costs. |

|

Cost-Effective Maintenance |

Advanced machines are designed for easy maintenance with minimal downtime, reducing long-term maintenance costs and enhancing machine longevity. |

Maintenance and Troubleshooting

Proper maintenance and effective troubleshooting are essential for ensuring the longevity and optimal performance of an automatic biscuit making machine. As an industrial food machinery expert, it is critical to follow a structured approach to keep the equipment running smoothly and minimize downtime.

Routine Maintenance Tips

1. Regular Cleaning:

Daily Cleaning: Clean all contact surfaces and remove any dough residues to prevent contamination and ensure hygiene.

Weekly Deep Cleaning: Disassemble parts such as mixers, forming molds, and conveyors for thorough cleaning to remove buildup and prevent mechanical issues.

2. Lubrication:

Scheduled Lubrication: Regularly lubricate moving parts like bearings, gears, and chains to reduce friction and wear.

Use Manufacturer-Recommended Lubricants: Always use lubricants specified by the machine manufacturer to avoid damage and ensure optimal performance.

3. Inspection and Replacement of Parts:

Routine Inspections: Conduct visual and operational inspections weekly to identify signs of wear or damage.

Replace Worn-Out Parts: Timely replacement of worn-out or damaged components such as belts, rollers, and seals to prevent breakdowns.

4. Calibration and Adjustment:

Regular Calibration: Periodically calibrate sensors, mixers, and forming machines to maintain precision in dough mixing and biscuit forming.

Adjust Settings: Ensure that all machine settings are correctly adjusted according to the manufacturer's specifications and production requirements.

Common Issues and Solutions

1. Inconsistent Biscuit Shapes:

Possible Cause: Incorrect dough consistency or worn-out molds.

Solution: Adjust the dough recipe for proper consistency and replace worn-out molds.

2. Machine Jamming:

Possible Cause: Dough buildup or foreign objects in the machine.

Solution: Clean the machine thoroughly to remove any blockages and ensure that the dough feeder operates smoothly.

3. Uneven Baking:

Possible Cause: Incorrect oven temperature settings or blocked airflow.

Solution: Check and adjust oven temperature settings and ensure that there is no obstruction in the airflow.

4. Excessive Noise:

Possible Cause: Lack of lubrication or worn-out mechanical parts.

Solution: Lubricate moving parts regularly and replace any worn-out components.

Extending the Lifespan of Your Machine

1. Training and Supervision:

Operator Training: Ensure that all operators are well-trained in machine operation and maintenance procedures.

Supervision: Regularly supervise machine operations to ensure adherence to maintenance protocols.

2. Preventive Maintenance Schedule:

Implement a Schedule: Establish a preventive maintenance schedule based on the manufacturer's recommendations.

Document Maintenance Activities: Keep detailed records of all maintenance activities, including inspections, cleanings, and part replacements.

3. Using Genuine Parts:

Purchase from Manufacturer: Always use genuine parts from the machine manufacturer to ensure compatibility and reliability.

Avoid Counterfeit Parts: Counterfeit parts can lead to poor performance and potential machine damage.

Innovations and Advances in 2024

The year 2024 marks significant advancements in the field of automatic biscuit making machines, driven by technological innovations aimed at enhancing efficiency, sustainability, and product quality. As an industrial food machinery expert, it is essential to stay updated with these developments to leverage new capabilities and maintain a competitive edge.

1.Technological Enhancements

Artificial Intelligence and Machine Learning:

Predictive Maintenance: AI-driven systems predict potential machine failures before they occur, reducing downtime and maintenance costs.

Optimized Production: Machine learning algorithms optimize production parameters for maximum efficiency and consistent product quality.

Internet of Things (IoT) Integration:

Real-Time Monitoring: IoT-enabled devices provide real-time data on machine performance, helping operators make informed decisions and quickly address issues.

Remote Control and Management: Operators can monitor and control the biscuit making process remotely, increasing flexibility and operational efficiency.

2.Energy Efficiency and Sustainability

Eco-Friendly Designs:

Energy-Efficient Components: Modern machines are equipped with energy-efficient motors and baking ovens, reducing power consumption and operational costs.

Sustainable Materials: Use of recyclable and biodegradable materials in machine construction and packaging, aligning with global sustainability goals.

Waste Reduction Technologies:

Precision Forming and Cutting: Advanced forming and cutting technologies minimize dough waste, ensuring optimal use of raw materials.

Closed-Loop Systems: Integration of closed-loop systems for recycling waste materials within the production process, further reducing environmental impact.

3.Integration with Smart Baking Solutions

Smart Baking Systems:

Automated Recipe Adjustments: Smart baking systems adjust recipes automatically based on ingredient quality and environmental conditions, ensuring consistent product quality.

Enhanced Data Analytics: Advanced data analytics provide insights into production trends, helping to improve processes and product development.

Advanced Quality Control:

Real-Time Quality Checks: Continuous quality monitoring using sensors and cameras to detect defects and ensure each biscuit meets stringent quality standards.

Automated Sorting: Automated sorting systems identify and remove defective biscuits from the production line, maintaining high product standards.

References

The following are five authoritative foreign literature websites in the field of industrial food machines:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Journal of Food Engineering

Website: [https://www.journals.elsevier.com/journal-of-food-engineering]

5. ResearchGate

Website: [https://www.researchgate.net/]