The Ultimate Japanese Panko Bread Crumb Extruder Guide to 2024

Introduction to Japanese Panko Bread Crumb Extruders

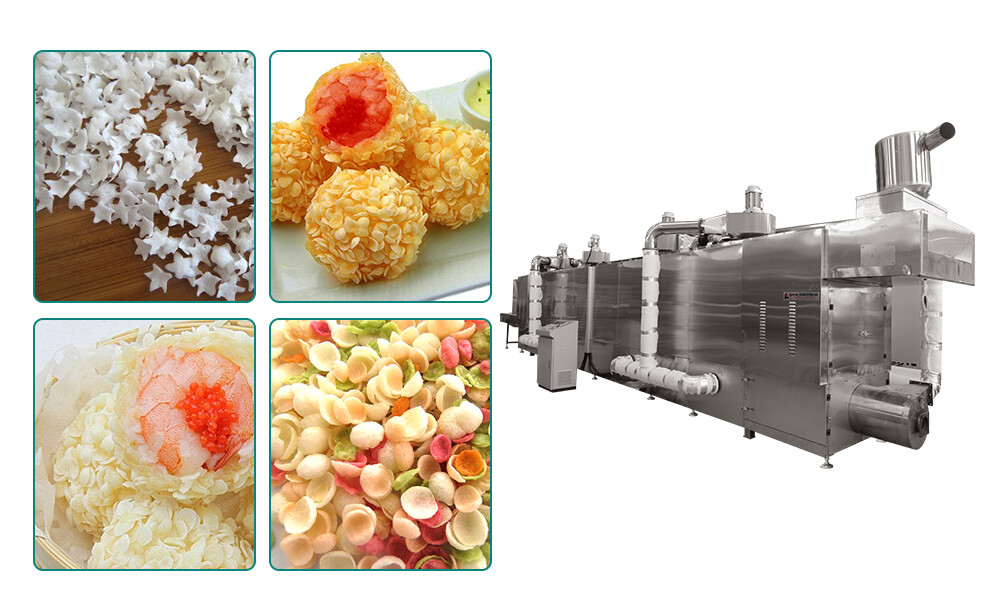

Japanese panko bread crumb extruders are specialized machines designed to produce panko bread crumbs, a staple in Japanese cuisine known for their light, airy texture and superior crispiness. Panko bread crumbs are widely used in various culinary applications, from coating fried foods to adding texture to baked dishes. The production of these high-quality bread crumbs requires precision equipment, which is where Japanese panko bread crumb extruders come into play.

The importance of using a high-quality extruder cannot be overstated. These machines ensure consistency in crumb size and texture, which is critical for achieving the desired culinary results. Unlike traditional bread crumb production methods, extruders streamline the process, making it more efficient and scalable. As demand for panko continues to grow globally, the adoption of advanced extruders has become essential for manufacturers.

In 2024, the market for panko bread crumbs is expected to expand further, driven by the increasing popularity of Japanese cuisine and the rising trend of incorporating panko into various recipes. This guide aims to provide a comprehensive overview of Japanese panko bread crumb extruders, highlighting their key features, operational mechanisms, and the latest advancements in the industry.

Key Features of Panko Bread Crumb Extruders

|

Feature |

Description |

| Precision Control | Allows for accurate control over crumb size and texture, ensuring uniformity in the final product. |

| High Throughput | Capable of processing large quantities of bread, meeting the demands of industrial-scale production. |

| Energy Efficiency | Designed to minimize energy consumption, reducing operational costs and environmental impact. |

| Durable Construction | Made from high-quality materials to withstand continuous use and harsh production environments. |

| Automated Operation | Equipped with advanced automation for minimal human intervention and increased productivity. |

| Easy Maintenance | Features easy-to-clean components and accessible design for routine maintenance. |

| Versatility | Adjustable settings to produce different types of bread crumbs, including coarse and fine variations. |

| Safety Features | Includes safety mechanisms to protect operators and ensure safe operation of the machinery. |

| Real-time Monitoring | Integration with IoT technology for real-time monitoring and control of the production process. |

| Compact Design | Space-efficient design suitable for various production facilities, from small bakeries to large factories. |

How Panko Bread Crumb Extruders Work

Japanese panko bread crumb extruders are sophisticated machines designed to produce high-quality panko bread crumbs, a staple in Japanese cuisine. These extruders operate through a multi-step process that ensures the production of uniformly shaped and textured bread crumbs.

The process begins with the preparation of the dough. Ingredients are mixed in precise proportions to form a dough with the ideal consistency. This dough is then fed into the extruder's hopper, where it undergoes further processing. Inside the extruder, the dough is subjected to high pressure and temperature, causing it to cook and expand.

Next, the dough is pushed through specially designed extrusion dies. These dies shape the dough into a continuous sheet or strand, depending on the desired crumb texture. The unique structure of the dies ensures that the crumbs have the characteristic light and airy texture of traditional panko bread crumbs.

After extrusion, the shaped dough is cut into smaller pieces and moved to the drying stage. The drying process is crucial as it removes moisture from the crumbs, enhancing their crispiness and shelf life. Modern extruders often incorporate advanced drying systems that ensure uniform drying without compromising the texture of the crumbs.

Finally, the dried crumbs are cooled and sifted to remove any irregular pieces. The final product is then ready for packaging. This entire process, from dough preparation to final packaging, is highly automated, ensuring consistent quality and efficiency in the production of Japanese panko bread crumb extruders.

Benefits of Using Japanese Panko Bread Crumb Extruders

|

Benefit |

Description |

| High Efficiency | Japanese panko bread crumb extruders are designed to maximize production efficiency, allowing for high output with minimal downtime. This ensures that manufacturers can meet large-scale demands without compromising on quality. |

| Consistent Quality | These extruders produce uniformly shaped and textured bread crumbs, maintaining the high standards expected in panko production. Consistency is key in ensuring that every batch meets consumer expectations. |

| Automation and Precision | Advanced automation features in Japanese panko bread crumb extruders enable precise control over every aspect of the production process, from dough mixing to drying. This reduces human error and enhances product uniformity. |

| Energy Efficiency | Modern extruders are built with energy-efficient components that reduce overall energy consumption. This not only lowers operational costs but also minimizes the environmental impact of the production process. |

| Versatility | These extruders can be adjusted to produce different types and sizes of bread crumbs, catering to various culinary applications. This versatility makes them a valuable asset for manufacturers looking to diversify their product offerings. |

| Ease of Maintenance | Designed with user-friendly features, Japanese panko bread crumb extruders require minimal maintenance. Accessible components and straightforward cleaning procedures ensure that the machines remain in optimal working condition with minimal downtime. |

| Innovative Technology | Incorporating the latest technological advancements, these extruders offer features such as real-time monitoring, automatic adjustments, and IoT integration, enhancing overall production efficiency and product quality. |

| Food Safety Compliance | These extruders are built to meet stringent food safety standards, ensuring that the final product is safe for consumption. This includes features such as hygienic design, easy cleaning, and materials that comply with food safety regulations. |

| Cost-Effective Production | By improving efficiency and reducing waste, Japanese panko bread crumb extruders help lower production costs. This makes it economically viable for manufacturers to produce high-quality bread crumbs on a large scale. |

| Enhanced Product Shelf Life | The precise drying and cooling mechanisms in these extruders ensure that the bread crumbs have a longer shelf life, maintaining their crispiness and freshness over time. |

This detailed guide on Japanese panko bread crumb extruders provides a comprehensive overview of their working principles and benefits, ensuring a thorough understanding of their role in industrial food production.

Selecting the Right Panko Bread Crumb Extruder

|

Criteria |

Description |

Key Considerations |

| Production Capacity | The amount of bread crumbs the extruder can produce per hour. | Match with your production needs. |

| Extruder Type | Single-screw or twin-screw extruders. | Twin-screw offers better mixing capabilities. |

| Power Consumption | The energy usage of the extruder. | Ensure energy efficiency for cost savings. |

| Build Material | Materials used in construction, such as stainless steel. | Stainless steel is preferred for durability. |

| Control System | Type of control system, such as PLC (Programmable Logic Controller). | PLC systems provide precise control. |

| Customization Options | Availability of custom features to meet specific production requirements. | Flexibility to adapt to various needs. |

| Maintenance Requirements | Ease of maintenance and availability of spare parts. | Low maintenance and readily available parts. |

| Brand Reputation | The reliability and reputation of the manufacturer. | Choose reputable brands with good support. |

| Cost | Initial purchase price and long-term operational costs. | Consider both upfront and ongoing costs. |

| Compliance | Adherence to industry standards and regulatory requirements. | Ensure compliance with local and international standards. |

Maintenance Tips for Panko Bread Crumb Extruders

Conduct routine inspections to identify any signs of wear or damage.Clean the extruder thoroughly after each production cycle to prevent buildup and contamination.Utilize appropriate cleaning agents that do not damage the equipment.

Regularly lubricate moving parts as recommended by the manufacturer. Proper lubrication reduces friction, prevents wear, and extends the lifespan of components.Use high-quality, food-grade lubricants to ensure safety and compliance with food production standards.

Monitor critical components such as screws, barrels, and seals for signs of wear. Replace these parts promptly to avoid breakdowns and ensure consistent production quality.Keep a stock of essential spare parts to minimize downtime during replacements.

Periodically calibrate the control systems and sensors to ensure accurate operation. Proper calibration ensures the extruder operates within specified parameters, producing uniform bread crumbs.Conduct regular performance tests to verify that the extruder meets production standards. Testing helps in early detection of potential issues and maintaining quality control.

Common Issues and Troubleshooting for Panko Extruders

|

Issue |

Description |

Troubleshooting Steps |

| Inconsistent Crumb Size | Variation in the size of bread crumbs produced. | Check the extruder settings, ensure uniform dough consistency, clean the extrusion die regularly. |

| Overheating | Extruder becomes excessively hot during operation. | Verify cooling system functionality, reduce production speed, ensure proper ventilation around the extruder. |

| Blocked Extrusion Die | Dough or crumbs block the extrusion die, halting production. | Disassemble and clean the die, inspect for any damage, ensure dough consistency is appropriate. |

| Mechanical Jams | Moving parts of the extruder get stuck, causing stoppages. | Lubricate moving parts regularly, inspect for worn-out components, remove any foreign objects. |

| Uneven Dough Feed | Dough does not enter the extruder evenly, leading to inconsistent output. | Adjust dough feeder settings, check for blockages in the feeder system, ensure even dough preparation. |

| Motor Malfunctions | Extruder motor fails to operate correctly, leading to stoppages or reduced performance. | Check electrical connections, inspect the motor for overheating, perform regular maintenance checks. |

| Excessive Noise | Unusual noises during operation indicating possible mechanical issues. | Lubricate parts, tighten any loose components, inspect for damage to moving parts. |

| Poor Crumb Texture | Bread crumbs have an undesirable texture, not meeting quality standards. | Adjust extrusion temperature and pressure, ensure proper dough consistency, clean the extrusion die. |

Innovations in Panko Bread Crumb Extrusion Technology

Innovations in Japanese panko bread crumb extruder technology have significantly advanced the production process, resulting in higher efficiency and better product quality. One notable innovation is the integration of smart sensors and IoT technology. These sensors provide real-time data on the extruder’s performance, such as temperature, pressure, and dough consistency. This data can be monitored remotely, allowing for immediate adjustments and minimizing downtime.

Another significant development is the introduction of energy-efficient motors and drives. These new motors reduce energy consumption without compromising on performance. By using variable frequency drives (VFDs), the extruders can adjust their speed according to the production requirements, optimizing energy use and reducing operational costs.

The design of extrusion dies has also seen improvements. Modern dies are made from advanced materials that offer better resistance to wear and tear. These materials also provide a more consistent extrusion, resulting in uniform crumb size and texture. Additionally, some extruders now feature self-cleaning dies, which reduce the time needed for maintenance and improve overall efficiency.

Furthermore, the latest extruders come with enhanced user interfaces. These interfaces are more intuitive and user-friendly, allowing operators to control the machine with greater ease. They also include diagnostic tools that help identify issues quickly and provide solutions, minimizing the time required for troubleshooting and repairs.

Energy Efficiency in Panko Bread Crumb Extruders

Energy efficiency in Japanese panko bread crumb extruders is a critical factor for modern manufacturers aiming to reduce costs and environmental impact. One of the primary advancements in this area is the use of variable frequency drives (VFDs). VFDs allow the motor speed to be adjusted according to the load, which means the extruder only uses as much energy as needed at any given time. This can result in substantial energy savings, especially during periods of low demand.

Another innovation is the development of high-efficiency heating elements. These elements are designed to provide consistent and precise heat while using less energy. They achieve this through improved insulation and more efficient heat transfer mechanisms, which reduce the amount of energy wasted during the heating process.

The introduction of recirculating cooling systems also contributes to energy efficiency. These systems reuse the cooling water, significantly reducing the amount of energy required to cool the extruder. By maintaining an optimal temperature with minimal energy input, these systems enhance the overall efficiency of the production line.

Manufacturers are also exploring renewable energy sources to power their extruders. Solar panels and wind turbines can be integrated into the production facility to provide a sustainable energy supply. This not only reduces reliance on traditional energy sources but also lowers the carbon footprint of the manufacturing process.

By focusing on these energy-efficient technologies, manufacturers can reduce operational costs and contribute to environmental sustainability. The adoption of such innovations ensures that panko bread crumb production remains economically viable and environmentally responsible in the years to come.

Conclusion

The evolution of Japanese panko bread crumb extruder technology has paved the way for unprecedented efficiency, quality, and sustainability in the food processing industry. With innovations such as smart sensors, energy-efficient motors, and advanced extrusion dies, manufacturers can now achieve higher production rates while reducing energy consumption and minimizing environmental impact.

Moreover, the integration of user-friendly interfaces and diagnostic tools has simplified operation and maintenance, ensuring smooth and uninterrupted production processes. Looking ahead to 2024 and beyond, the continued advancement of panko bread crumb extruder technology promises even greater improvements in performance and cost-effectiveness. As manufacturers embrace these innovations and strive for excellence in their operations, consumers can expect to enjoy consistently high-quality panko bread crumbs that meet the demands of modern culinary applications.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com