Everything you need to know about industrial microwave dryer in 2024

Introduction

In the realm of modern food processing, the utilization of cutting-edge technologies has become paramount to meet the growing demands for efficiency, quality, and sustainability. Among these technologies, the industrial microwave dryer stands out as a versatile and indispensable tool for achieving rapid and uniform drying of various food products.

The year 2024 marks a significant milestone in the evolution of industrial microwave dryers, with advancements in design, functionality, and integration shaping the landscape of food processing. As we delve into the intricacies of industrial microwave drying technology, it becomes apparent that a comprehensive understanding of its principles, applications, and benefits is essential for stakeholders across the food industry.

Throughout this guide, we will explore everything you need to know about industrial microwave dryers in 2024. From their working principles and components to their applications across different industries, we aim to provide you with valuable insights into the transformative capabilities of this innovative technology. Join us on this journey as we unravel the complexities and possibilities of industrial microwave drying in the year 2024 and beyond.

Working Principle of Industrial Microwave Dryer

1. Microwave Heating Mechanism:

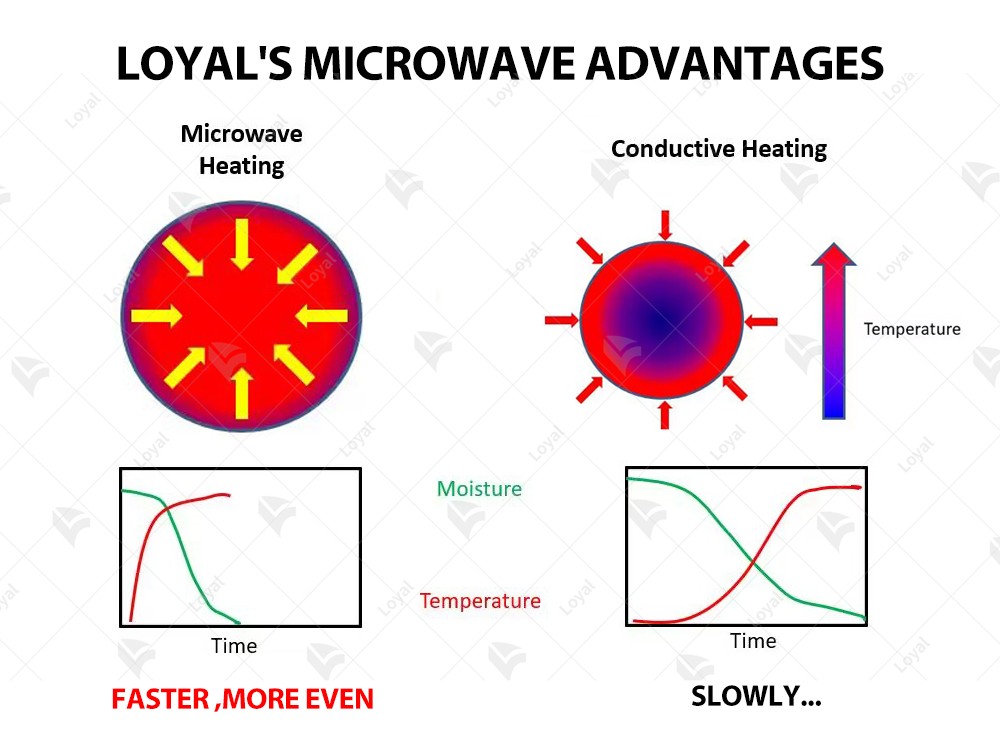

The fundamental principle behind industrial microwave dryers lies in the application of electromagnetic waves, specifically microwaves, to generate heat within the product being dried. These microwaves penetrate the material and interact with its molecules, causing them to oscillate rapidly. As a result of this molecular agitation, friction is generated, leading to the conversion of microwave energy into heat. Unlike conventional dryers that rely on external heat sources to transfer energy to the product surface, industrial microwave dryers heat the product internally, enabling faster and more uniform drying.

2. Uniform Heating and Moisture Removal:

Unlike traditional drying methods, which often result in uneven drying and moisture gradients, microwave dryers offer precise control over the drying process. By adjusting parameters such as microwave power, frequency, and time, operators can tailor the drying conditions to suit the specific characteristics of the product. This uniform heating ensures consistent product quality and minimizes the risk of over-drying or under-drying, thereby enhancing efficiency and reducing processing time.

Advantages of industrial microwave dryers

|

Advantages |

Description |

|

Rapid Drying |

Industrial microwave dryers facilitate rapid drying, significantly reducing processing time compared to conventional methods. |

|

Uniform Heating |

Microwave technology ensures uniform heating throughout the product, minimizing the risk of uneven drying and ensuring consistent quality. |

|

Energy Efficiency |

Industrial microwave dryers are highly energy-efficient, utilizing electromagnetic waves to directly heat the product, reducing energy consumption and operating costs. |

|

Preservation of Nutrients |

Unlike conventional drying methods that may degrade nutrients, industrial microwave dryers can preserve the nutritional content of food products more effectively. |

|

Improved Product Quality |

The precise control offered by industrial microwave dryers results in superior product quality, with minimal loss of flavor, color, and texture. |

|

Space-Saving Design |

Industrial microwave dryers often have a compact design, requiring less floor space compared to traditional drying equipment, making them suitable for smaller facilities. |

|

Reduced Labor Requirements |

Automation features in industrial microwave dryers streamline the drying process, reducing the need for manual intervention and labor, thus improving operational efficiency. |

|

Versatility |

Industrial microwave dryers can be used for a wide range of applications, from drying fruits, vegetables, and grains to heating, sterilizing, and thawing various food products. |

Key components of industrial microwave dryers

|

Component |

Description |

|

Magnetron |

The magnetron is the heart of the microwave dryer, generating electromagnetic waves. |

|

Waveguide |

Transmits microwave energy from the magnetron to the drying chamber. |

|

Drying Chamber |

The enclosed space where the food product is placed for drying. |

|

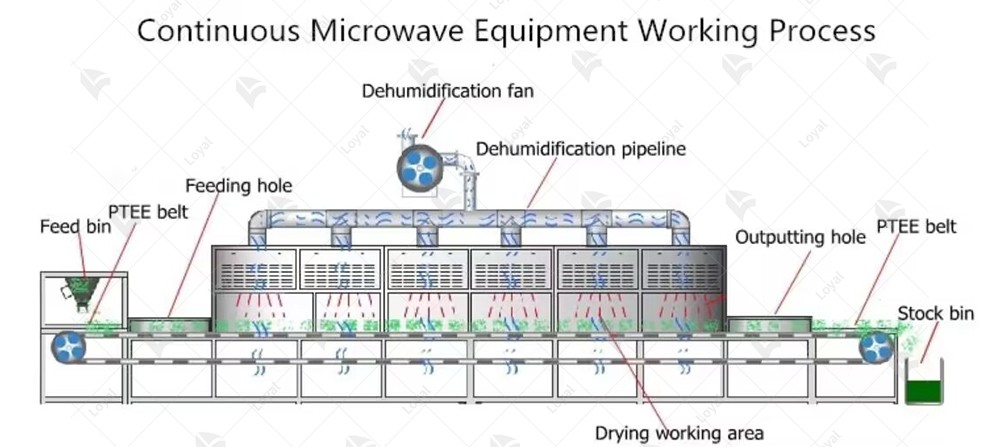

Conveyor System |

Transports the food product through the drying chamber at a controlled speed. |

|

Temperature Sensor |

Monitors the temperature inside the drying chamber to ensure optimal drying conditions. |

|

Humidity Sensor |

Measures the humidity level inside the drying chamber for precise control of drying process. |

|

Control Panel |

Interface for operators to set drying parameters and monitor the drying process. |

|

Safety Interlocks |

Ensures safe operation by shutting down the system if certain conditions are not met. |

|

Cooling System |

Prevents overheating of components and maintains optimal operating temperature. |

|

Exhaust System |

Removes excess moisture and gases from the drying chamber to maintain desired conditions. |

Types of Industrial Microwave Dryers

1. Batch Microwave Dryers:

Batch microwave dryers are designed to process a predetermined quantity of material in each cycle. These dryers feature a chamber where the material is loaded for drying, and once the cycle is complete, the dried product is removed, and a new batch can be loaded. Batch dryers are suitable for applications where consistent drying conditions are essential, such as in research laboratories or small-scale production facilities.

2. Continuous Microwave Dryers:

Continuous microwave dryers are designed for high-volume production environments, where a continuous flow of material needs to be dried. These dryers feature a conveyor belt or other continuous material handling mechanism that transports the product through the drying chamber at a consistent rate. Continuous dryers offer higher throughput compared to batch dryers and are commonly used in large-scale industrial operations such as food processing plants and pharmaceutical manufacturing facilities.

3. Hybrid Microwave Dryers:

Hybrid microwave dryers combine microwave technology with conventional drying methods such as hot air convection or infrared radiation. This hybrid approach allows for greater flexibility in controlling the drying process and can result in improved product quality and energy efficiency. Hybrid dryers are particularly beneficial for drying delicate or heat-sensitive materials that may be prone to uneven drying or overheating when subjected to microwave radiation alone.

4. Vacuum Microwave Dryers:

Vacuum microwave dryers operate under reduced pressure conditions, which lowers the boiling point of water and facilitates faster drying. By combining microwave energy with vacuum technology, these dryers can achieve rapid and efficient drying while minimizing heat damage to sensitive materials. Vacuum microwave dryers are commonly used in industries such as pharmaceuticals, where preserving the integrity of active ingredients is critical.

Technical parameters

|

Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine |

|||||

|

Model |

Size LWH(Can be customized according |

Output |

Dewaterability |

Sterilization |

Baking and Roasting capacity |

|

LY-10KW |

5000mm825mm1750mm |

≥10KW |

10KG/Hour |

100KG/Hour |

30-50KG/Hour |

|

LY-20KW |

8000mm825mm1750mm |

≥20KW |

20KG/Hour |

200KG/Hour |

60-100KG/Hour |

|

LY-30KW |

8500mm1160mm1750mm |

≥30KW |

30KG/Hour |

300KG/Hour |

90-150 KG/Hour |

|

LY-40KW |

10000mm1160mm1750mm |

≥40KW |

40KG/Hour |

40KG/Hour |

120-200KG/Hour |

|

LY-50KW |

12500mm1160mm1750mm |

≥50KW |

50KG/Hour |

500KG/Hour |

150-250KG/Hour |

|

LY-60KW |

13500mm1450mm1750mm |

≥60KW |

60KG/Hour |

600KG/Hour |

180-300KG/Hour |

|

LY-70KW |

13500mm1500mm1750mm |

≥70KW |

70KG/Hour |

700KG/Hour |

210-350KG/Hour |

|

LY-80KW |

13500mm1650mm1750mm |

≥80KW |

80KG/Hour |

800KG/Hour |

240-400KG/Hour |

|

LY-100KW |

16800mm1650mm1750mm |

≥100KW |

100KG/Hour |

1000KG/Hour |

300-500KG/Hour |

|

LY-150KW |

22400mm1850mm1750mm |

≥150KW |

150KG/Hour |

1500KG/Hour |

450-750KG/Hour |

|

LY-200KW |

27000mm1850mm1750mm |

≥250KW |

250KG/Hour |

2500KG/Hour |

750-1250/Hour |

|

LY-300KW |

32000mm1850mm1750mm |

≥300KW |

300KG/Hour |

3000KG/Hour |

900-1500KG/Hour |

|

Power Supply |

380V±10% 50Hz±1% Three-Phase Five-Wire |

||||

|

Microwave Output Frequency |

2450±50Mhz |

||||

|

Microwave Input Apparent Power |

≤168Kva |

||||

|

Microwave Output Power |

≥120Kw |

||||

|

Microwave Power Adjustment Range |

0-30Kw(Adjustable) |

||||

|

Ambient Temperature |

-5-40°C |

||||

|

Relative Humidity |

≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas |

||||

|

Transmission Speed |

0-10m/Min(Adjustable) |

||||

Application of Industrial Microwave Ovens

Industrial microwave ovens find extensive application across a wide range of industries due to their versatility and efficiency. Here are some key areas where industrial microwave dryers are commonly used:

Food Processing Industry:

In the food processing industry, industrial microwave dryers play a crucial role in preserving food quality while achieving rapid and uniform drying. They are employed for drying fruits, vegetables, herbs, spices, meat products, and even ready-to-eat meals. Industrial microwave ovens help maintain the nutritional content, color, flavor, and texture of the food products, ensuring superior quality and extended shelf life.

Pharmaceutical Sector:

In pharmaceutical manufacturing, precision and consistency are paramount. Industrial microwave dryers are utilized for drying active pharmaceutical ingredients (APIs), herbal extracts, and pharmaceutical intermediates. The controlled heating provided by industrial microwave ovens helps prevent degradation of sensitive compounds, ensuring the potency and efficacy of pharmaceutical products.

Chemical Industry:

Industrial microwave dryers are also widely used in the chemical industry for drying various chemical compounds, catalysts, and intermediates. They offer advantages such as precise temperature control, rapid heating, and uniform drying, which are essential for maintaining product quality and purity. Industrial microwave ovens are preferred for their ability to handle heat-sensitive materials without compromising their integrity.

Textile Manufacturing:

In textile manufacturing, industrial microwave dryers are employed for drying fabrics, yarns, and textile finishes. They offer significant advantages over conventional drying methods, such as reduced drying times, improved energy efficiency, and enhanced fabric quality. Industrial microwave ovens help eliminate moisture quickly and uniformly, resulting in softer, smoother, and more consistent textiles.

Environmental Remediation:

Industrial microwave dryers are increasingly being utilized for environmental remediation purposes, such as drying contaminated soils, sludges, and industrial waste materials. The rapid and efficient drying capabilities of industrial microwave ovens facilitate the removal of moisture and volatile organic compounds (VOCs), aiding in the remediation process and reducing environmental pollution.

Precautions for Selecting and Implementing Industrial Microwave Dryers

When considering the adoption of industrial microwave dryers in your food processing facility in 2024, it's crucial to exercise caution and follow certain precautions to ensure optimal performance and safety. Here are some key considerations:

1. Capacity and Throughput Requirements:

Before selecting an industrial microwave dryer, carefully assess your production needs in terms of capacity and throughput. Ensure that the chosen dryer can handle the volume of material you intend to process efficiently without compromising on drying quality.

2. Power and Energy Consumption:

Industrial microwave dryers come in various power ratings. Choose a model that strikes the right balance between power and energy consumption based on your operational requirements and budget constraints. Opt for energy-efficient models to minimize operating costs over the long term.

3. Material Compatibility:

Different materials may have varying susceptibilities to microwave drying. Ensure that the industrial microwave dryer you select is compatible with the specific type of material you plan to dry. Consider factors such as moisture content, density, and composition when evaluating compatibility.

4. Safety Features:

Prioritize safety when selecting an industrial microwave dryer. Look for models equipped with safety features such as temperature and moisture sensors, automatic shut-off mechanisms, and built-in alarms to prevent overheating or other potential hazards.

5. Installation and Maintenance Requirements:

Consider the installation and maintenance requirements of the industrial microwave dryer. Ensure that your facility has the necessary infrastructure, such as adequate electrical connections and ventilation, to support the dryer's operation safely. Additionally, establish a routine maintenance schedule to keep the dryer functioning optimally and prolong its lifespan.

6. Regulatory Compliance:

Verify that the industrial microwave dryer complies with relevant regulatory standards and industry guidelines for food processing equipment. Ensure that it meets all safety and sanitation requirements to avoid regulatory issues and ensure consumer safety.

7. Training and Operator Competency:

Provide comprehensive training to operators responsible for operating the industrial microwave dryer. Ensure that they understand proper operating procedures, safety protocols, and troubleshooting techniques to minimize the risk of accidents or operational errors.

8. Performance Monitoring and Quality Control:

Implement robust performance monitoring and quality control measures to ensure consistent drying results. Regularly monitor key parameters such as temperature, moisture levels, and drying time to detect any deviations from the desired specifications and take corrective action promptly.

9. Trial Runs and Testing:

Before fully integrating an industrial microwave dryer into your production line, conduct trial runs and testing to evaluate its performance under real-world conditions. Adjust settings and parameters as needed to optimize drying efficiency and product quality.

10. Supplier Reputation and Support:

Choose a reputable supplier with a track record of providing reliable industrial microwave dryers and excellent customer support. Opt for suppliers who offer comprehensive warranty coverage, technical assistance, and timely maintenance services to address any issues that may arise during operation.

Post-maintenance of industrial microwave dryer

|

Post-Maintenance Task |

Description |

|

Cleaning |

Regular cleaning of the interior and exterior surfaces to remove debris and residue. |

|

Inspection |

Thorough inspection of all components, including magnetrons, waveguides, and seals, for signs of wear or damage. |

|

Calibration |

Calibration of power settings and temperature controls to maintain consistency and accuracy in drying processes. |

|

Safety Check |

Verification of safety features and emergency shut-off systems to ensure compliance with regulatory standards. |

|

Component Replacement |

Replacement of worn or damaged components, such as seals, belts, or cooling fans, to prevent equipment failure. |

|

Performance Testing |

Performance testing to verify that the industrial microwave dryer meets specified drying parameters and quality standards. |

|

Documentation Update |

Updating maintenance records and documentation to track post-maintenance activities and ensure accountability. |

Conclusion

In conclusion, the industrial microwave dryer stands as a cornerstone technology in the landscape of food processing and beyond in 2024. Its unparalleled efficiency, precision, and versatility make it indispensable for industries seeking to optimize their drying processes while maintaining product quality and safety. As advancements continue to propel microwave drying technology forward, we anticipate even greater innovations and applications in the years to come, further solidifying its status as a key player in industrial drying solutions.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]