Revolutionizing Thawing Processes: Full Automation with Meat Defrosting Machine

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:Ispecc,Energy Beam Sciences Inc.

In the realm of food processing, the thawing of meat has always been a critical stage, influencing both quality and efficiency. This introduction sets the stage for a revolutionary transformation in thawing processes through the full automation offered by meat defrosting machines. As demand for processed meats rises, the need for efficient thawing methods becomes more pressing.

Traditional thawing methods have long been a bottleneck in the meat processing industry. From natural thawing to water immersion, each method has its drawbacks. This section provides an in-depth overview of existing thawing processes, emphasizing the limitations that have paved the way for innovative solutions.

With the escalating demand for processed meat products, the inefficiencies of manual thawing processes have become apparent. This section delves into the necessity for automation in meat defrosting, addressing the challenges posed by the conventional methods and highlighting the potential for increased efficiency and precision.

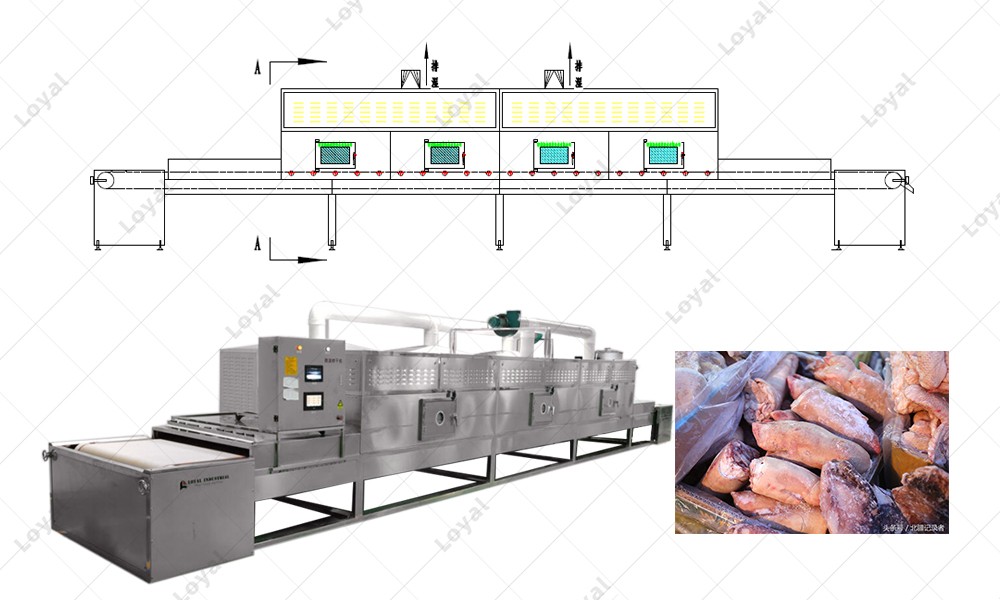

The emergence of meat defrosting machines marks a pivotal moment in the food processing industry. This section explores the technological advancements that have led to the development of these machines, providing a glimpse into how they are revolutionizing the traditional approach to meat thawing.

Understanding Meat Defrosting Machines

Meat defrosting machines leverage innovative principles for rapid thawing. The utilization of controlled temperatures and airflow accelerates the thawing process significantly, reducing the time required without compromising the integrity of the meat.

Air-based systems utilize a carefully regulated airflow to thaw meat efficiently. This section details the mechanisms behind air-based defrosting and highlights its advantages in preserving the natural texture and flavor of the meat.

Water immersion techniques have been a traditional approach, but with automation, they have reached new levels of efficiency. This subsection explores how automated water immersion systems optimize the thawing process.

Advantages of Full Automation

The implementation of meat defrosting machines brings a paradigm shift in efficiency. By automating the thawing process, the time required for this crucial step is significantly reduced, allowing meat processing facilities to handle larger volumes without compromising on quality. Meat defrosting machine technology ensures a streamlined workflow, contributing to overall operational efficiency.

One of the paramount concerns in the meat processing industry is maintaining the quality of the final product. This section delves into how meat defrosting machines play a pivotal role in preserving the texture, flavor, and nutritional value of the meat. Automated processes minimize the risk of over-thawing, ensuring a consistently high-quality end product.

Automation not only accelerates thawing processes but also alleviates the dependence on manual labor. This subsection explores the cost-saving benefits of meat defrosting machines, shedding light on how businesses can optimize their resources by reducing the need for manual intervention. The result is a more cost-effective and streamlined operation.

In the context of evolving societal values, sustainability is a crucial consideration. This section discusses how the automation of meat thawing processes contributes to sustainability goals. From energy-efficient technologies to reduced water consumption, meat defrosting machines align with environmentally friendly practices, addressing concerns about the industry's ecological footprint.

Case Studies and Success Stories

This section explores real-world examples of how large-scale meat processing facilities have embraced the revolution in thawing processes. By incorporating meat defrosting machines into their operations, these facilities have experienced notable improvements in efficiency, quality, and overall productivity.

Drawing on concrete examples, this subsection examines how the adoption of meat defrosting machines translates into improved profit margins for businesses. The streamlined processes and enhanced product quality contribute to a competitive edge, attracting more customers and boosting financial returns.

The voices of industry experts provide credibility to the benefits of meat defrosting machines. This section includes testimonials and quotes from authoritative figures in the food processing domain, offering insights into the transformative impact of automation on meat thawing processes.

Challenges and Solutions

As with any technological advancement, concerns about food safety arise. This subsection addresses these concerns head-on, discussing how meat defrosting machines adhere to and, in many cases, exceed food safety standards. Automation, when implemented correctly, minimizes the risk of contamination and ensures that the final product meets stringent quality benchmarks.

While the benefits of meat defrosting machines are evident, the initial investment can be a barrier for some businesses. This section explores potential challenges associated with the upfront costs and presents strategies for overcoming these barriers. By emphasizing the long-term gains and return on investment, businesses can make informed decisions regarding the adoption of this transformative technology.

This subsection delves into the dynamic nature of the food processing industry and the need for continuous innovation. Meat defrosting machines serve as a prime example of how technology evolves to meet changing demands. By staying abreast of emerging trends and advancements, businesses can position themselves for sustained success in a competitive landscape.

Future Prospects and Trends

Artificial Intelligence (AI) is poised to play a pivotal role in the future of meat thawing processes. This section explores how AI can enhance the capabilities of meat defrosting machines, optimizing thawing parameters based on real-time data and adapting to varying meat types and sizes. The integration of AI promises unparalleled precision and efficiency.

Analyzing market trends and projections, this subsection provides insights into the anticipated growth of the meat defrosting machine market. As more businesses recognize the advantages of automation in meat processing, the global adoption of these machines is expected to rise, reshaping the landscape of the entire industry.

Machine Learning (ML) algorithms continue to evolve, presenting opportunities for further enhancements in meat thawing processes. This section explores potential advancements in ML algorithms that could revolutionize the precision, speed, and adaptability of meat defrosting machines in the coming years.

Conclusion

In conclusion, the journey through the evolution of meat thawing processes and the advent of meat defrosting machines underscores a transformative revolution in the food processing industry. From the limitations of traditional methods to the efficiency and precision offered by automation, the paradigm shift is unmistakable. Businesses that embrace this technological leap are positioned to redefine their approach to meat processing.

The recapitulation highlights how meat defrosting machines address longstanding challenges, from the need for speed and efficiency to the preservation of meat quality. The integration of innovative technologies, such as air-based systems and AI-driven algorithms, sets the stage for a new era in meat processing—one where automation is not just a convenience but a necessity.