Elevated Productivity: The High-Efficiency Journey with Fully Automatic Microwave Chili Powder Sterilization

Introduction

Shandong Loyal Industrial Co.,Ltd. a company specializing in manufacturing food processing equipment, headquartered in Shandong Province, China.The company adheres to the concept of "quality first, innovation leads" and is committed to providing high-quality, high-efficiency advanced equipment for the global food industry.We have established long-term cooperative relationships with many well-known food processing companies around the world, providing them with customized solutions. for example:DanTech UK Ltd,Thermex-Thermatron Systems.

Chili powder sterilization plays a pivotal role in ensuring the safety and quality of food products within the food processing industry. Manufacturers, however, face significant challenges in achieving high-efficiency sterilization due to the limitations of traditional methods. This article delves into the transformative journey facilitated by the Fully Automatic Microwave Chili Powder Sterilization Machine, highlighting its role in elevating productivity within this critical aspect of food production.

Evolution of Chili Powder Sterilization Technologies

To appreciate the significance of the Fully Automatic Microwave Chili Powder Sterilization Machine, we must first explore the historical methods employed for chili powder sterilization. As the food processing industry evolves to meet higher standards, the demand for advanced sterilization technologies has led to the development of fully automatic solutions, revolutionizing the efficiency and effectiveness of the process.

Technological Advancements in Automatic Microwave Chili Powder Sterilization

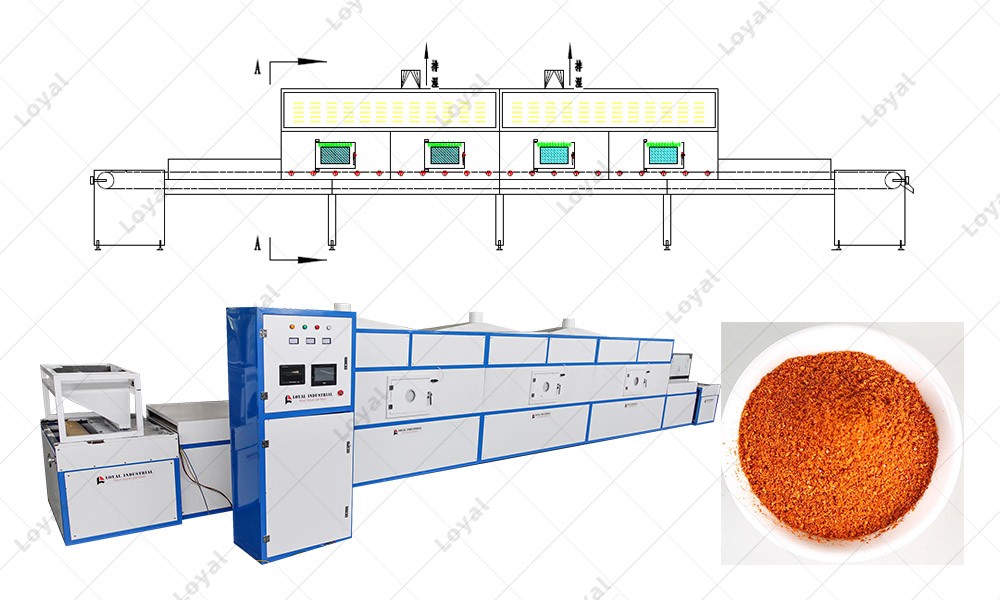

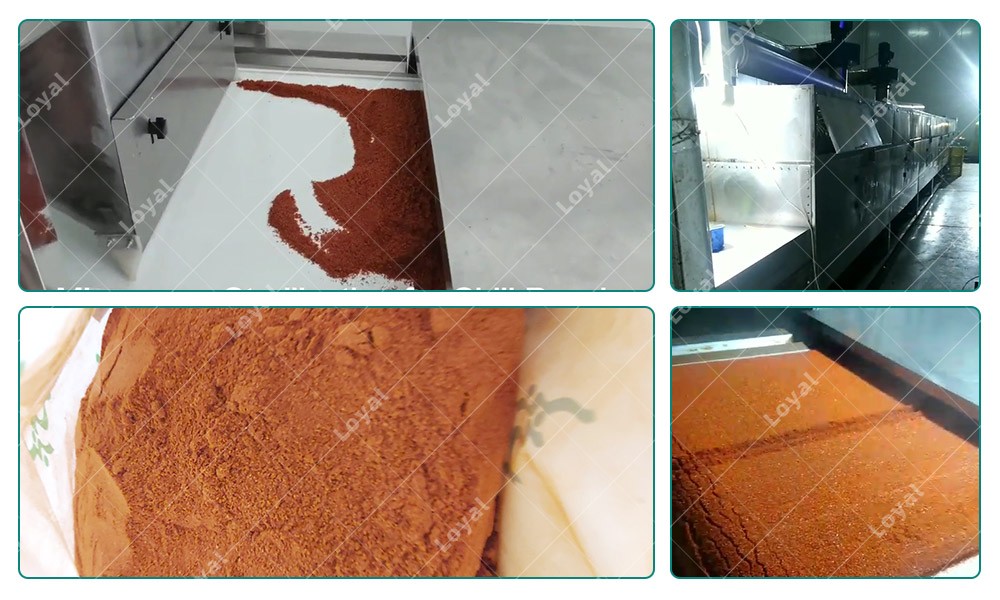

The Fully Automatic Microwave Chili Powder Sterilization Machine incorporates cutting-edge technology to revolutionize the efficiency of chili powder sterilization. With advanced features, this machine not only ensures the elimination of contaminants but also enhances the overall quality of the final product. The utilization of microwave technology allows for rapid and uniform sterilization, addressing the limitations of traditional methods. This section dives into specific technological advancements, showcasing how these features contribute to the machine's superior performance.

Precision and Quality in Sterilization

Precision is paramount in chili powder sterilization, as it directly impacts the quality of the end product. The fully automatic system employs state-of-the-art controls and monitoring mechanisms to ensure precise sterilization at every stage. This level of control not only safeguards against potential risks but also elevates the quality standards of chili powder manufacturing. By maintaining optimal conditions throughout the process, the machine surpasses traditional methods, providing manufacturers with a competitive edge in product integrity.

Integration into Chili Powder Processing

Examining the seamless integration of the Automatic Microwave Chili Powder Sterilization Machine into chili powder processing reveals real-world applications and case studies. These examples illustrate increased efficiency and productivity, emphasizing the adaptability of the machine to various stages of chili powder manufacturing. Whether applied during the grinding, blending, or packaging phases, the machine seamlessly integrates into existing processes, streamlining operations and enhancing overall production efficiency.

Advantages and Cost Efficiency

The fully automatic system presents a myriad of advantages for chili powder manufacturers. From a financial perspective, the economic benefits and cost efficiency are significant. Reduced processing time, minimized energy consumption, and lower operational costs contribute to the overall economic feasibility of adopting this advanced technology. This section delves into a detailed analysis of these advantages, providing manufacturers with a comprehensive understanding of the positive impact on their bottom line.

Technological Innovations and Future Trends

As technology continues to advance, the Fully Automatic Microwave Chili Powder Sterilization Machine evolves to meet emerging industry demands. Ongoing innovations, such as improved user interfaces, enhanced energy efficiency, and integration with Industry 4.0 technologies, ensure the machine remains at the forefront of chili powder sterilization. By anticipating future trends and advancements, manufacturers can make informed decisions about the long-term sustainability and relevance of this technology in their operations.

Environmental Sustainability

Environmental considerations are a crucial aspect of modern manufacturing. The article analyzes the environmental impact of the Fully Automatic Microwave Chili Powder Sterilization Machine, emphasizing its alignment with sustainability goals in the food processing industry. The reduction in energy consumption and waste, compared to traditional sterilization methods, positions the machine as an environmentally friendly solution, addressing the increasing importance of sustainable practices within the sector.

Regulatory Compliance and Safety

Manufacturers must adhere to strict regulatory standards and certifications to ensure the safety and quality of their products. This section explores how the fully automatic system meets these standards, highlighting the integrated safety measures. Certifications from relevant authorities validate the machine's compliance with industry regulations, providing manufacturers with confidence in its reliability and adherence to quality and safety standards.

Conclusion

In conclusion, the Fully Automatic Microwave Chili Powder Sterilization Machine stands as a transformative force in chili powder processing. By mastering full automation and leveraging advanced technologies, this machine elevates productivity and efficiency within the food processing industry. The article emphasizes the pivotal role it plays in ensuring high-quality, safe chili powder products. The call to action encourages manufacturers to embrace this advanced technology, setting the stage for enhanced productivity and excellence in the competitive landscape of the food processing industry.

Common Questions about Automatic Microwave Chili Powder Sterilization Machine

Q: How does the fully automatic system ensure precision in sterilization?

A: The precision of the system lies in its advanced controls and monitoring mechanisms. The machine maintains optimal conditions throughout the sterilization process, ensuring uniformity and accuracy. This precision guarantees the elimination of contaminants while preserving the quality and integrity of the chili powder.

Q: Can the machine be seamlessly integrated into existing chili powder processing lines?

A: Yes, the Fully Automatic Microwave Chili Powder Sterilization Machine is designed for seamless integration into various stages of chili powder manufacturing. Case studies have demonstrated its adaptability during grinding, blending, and packaging, showcasing increased efficiency without disrupting existing processes.

Q: What economic benefits and cost efficiency does the fully automatic system offer?

A: The economic advantages are multifaceted. Reduced processing time, lower energy consumption, and minimized operational costs contribute to overall cost efficiency. The fully automatic system optimizes resource utilization, providing a favorable economic impact for chili powder manufacturers.

Q: How does the machine align with sustainability goals in the food processing industry?

A: The machine reduces energy consumption and waste compared to traditional sterilization methods, aligning with the industry's sustainability goals. Its environmentally friendly features contribute to more sustainable practices in food processing, meeting the increasing demand for eco-friendly solutions.

Q: What safety measures are integrated into the fully automatic system?

A: The system incorporates advanced safety features, complying with regulatory standards. These measures include real-time monitoring, emergency shutdown protocols, and user-friendly interfaces that prioritize operator safety. Certifications from relevant authorities validate its adherence to industry safety standards.