Industrial Microwave Rubber Drying Technology

Introduction Of Microwave Rubber Drying Machine:

Microwave rubber drying machine is an advanced high-tech equipment that utilizes the electromagnetic waves of a microwave to rapidly and efficiently dry rubber products such as rubber sheets, rubber bands, rubber tubes, and other rubber materials. The microwave rubber drying machine is designed to dry rubber products with a high level of precision, ensuring that the rubber product is dried uniformly, without causing any damage or deformation to the rubber material.The microwave rubber drying machine is an environmentally friendly and energy-efficient method of drying rubber products, making it a preferred choice for many rubber processing factories.

Parameter Of Microwave Rubber Drying Machine:

Parameter Of Microwave Rubber Drying Machine:

|

1. Equipment Model |

LY-60HM (Continuous) |

|

2. Equipment Power |

90Kva |

|

3. Microwave Power |

60Kw (Adjustable) |

|

4. Equipment Size (Length*Width*Height) |

10520*1802*1750mm (Size Can Be Customized) |

|

5. Equipment Material |

The Whole Machine Is Made Of 304 Stainless Steel |

|

6. Equipment Capacity |

800~1000 Kg/Hour |

|

7.Equipment Color |

Silver |

Feature Of Microwave Rubber Drying Machine:

1. Efficiency: The microwave technology used in these machines ensures fast and efficient drying, reducing the total drying time significantly.

2. Uniformity: The microwave energy penetrates deeply and evenly into the rubber.

3. Control: These machines offer precise control of the temperature and moisture levels during the drying process, resulting in consistent drying quality.

4. Flexibility: Microwave rubber drying machines can be used for different types of rubber products, including extruded, molded, and latex products.

5. Safety: These machines are designed to operate safely with features such as interlocks, alarms, and overheat protection.

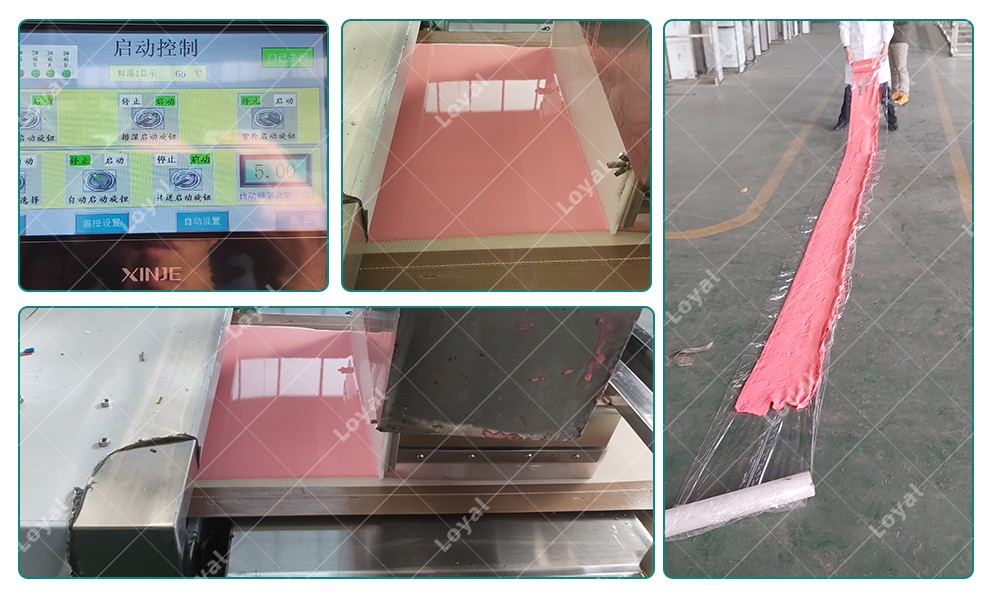

Details Display Of Microwave Rubber Drying Machine;

Applications Of Microwave Rubber Drying Machine:

|

1 |

Rubber manufacturing industry |

The drying machine is commonly used in the rubber manufacturing industry for drying natural and synthetic rubber products |

|

2 |

Automotive industry |

The machine is used for drying rubber components used in making automotive parts, such as rubber tires, hoses, and seals. |

|

3 |

Pharmaceutical industry |

The machine is used for drying rubber stoppers and seals used in pharmaceutical containers. |

|

4 |

Food industry |

The machine is used for drying rubber seals and gaskets used in food processing equipment. |

|

5 |

Medical industry |

The machine is used for drying rubber components used in medical devices such as catheters, tubing, and gloves. |

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Adopt Food Grade Stainless Steel, Nice Appearance, Easy To Clean.

2.Microwave Can Penetrate Through The Materials So That The Inside And Outside Are Heated At The Same Time, Short Processing Time,Evenly Drying And Thorough Terilization. No Extra Heat Loss, High Heat Efficiency, Saving Energy.

3.Thermal Effect And Non-Thermal Effect Work Together, Achieving Ideal Sterilization Effect At Low Temperature And Short Time, The Vegetable Can Keep Their Nutrition Components To The Maximum.

4.Adopt Non-Contact Infrared Temperature Measurement Technology, High Precision, Automatic Control.

5.Frequency Adjustable Conveyor Speed, Step-less Adjustable Microwave Power, Instant Heating And Stop, No Thermal Inertia,Convenient Operation.