How To Set Core Filling/inflating Snacks Factory?

Introduction Of Core Filling/Inflating Snacks Making Machine:

The core filling/inflating snacks making machine is a remarkable invention that has revolutionized the snack food industry. This machine is designed to produce delicious, high-quality snacks with a unique texture and flavor profile. It is capable of filling or inflating a variety of snack foods such as chips, corn curls, and other similar products with various fillings like cheese, chocolate, cream, etc.One of the most impressive features of this machine is its precision and consistency. It can produce snacks with a uniform size, shape, and filling quantity, which is essential for maintaining high product quality and customer satisfaction. Additionally, it is an efficient and cost-effective way to produce large quantities of snacks, which is important for meeting market demands.

The Core Filling/Inflating Snacks Production Line Details :

|

Capacity |

120kg-1000kg |

|

Power Supply |

Based on 380V 50 Hz 3 phase. Customized according to your local power. |

|

Machine details |

1.Stainless steel,:201, 304, 316, on request |

|

Certificate |

CE,GOST,TUV,BV |

|

Raw Material |

Wheat flour, corn, rice, oat, etc. |

|

Products Color |

White, Yellow |

|

Products type |

Core-filled potato chips, Core-filled corn curls,Core-filled wafers,Inflated snacks,etc. |

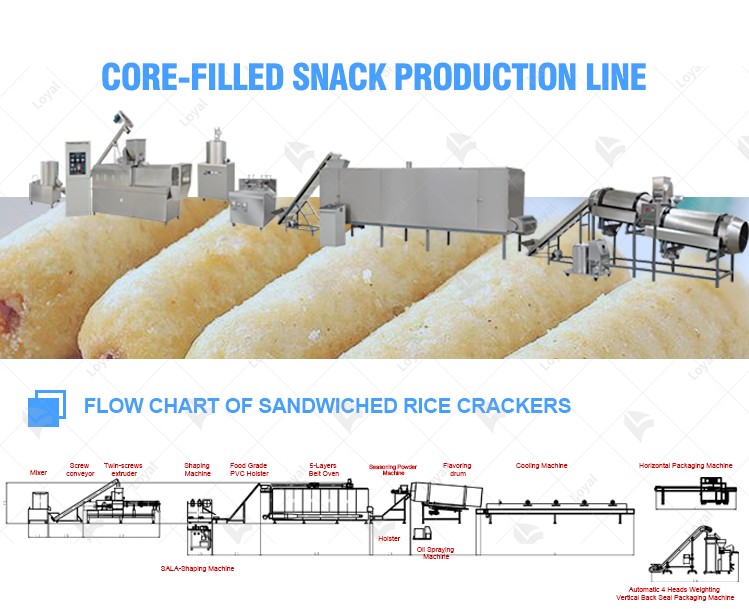

Flow Chart Of Commercial Core Filling/Inflating Snacks Processing Line:

Mixing → Extrusion → Drying → Baking → Seasoning → Cooling → Packaging

The Equipment Using In The Core Filling/Inflating Snacks Making Machine:

Powder Mixer --- Screw Conveyor --- Twin Screw Extruder --- Elevator / Air Feeder ---- Oven --- Seasoning Line --- Cooling Machine ---Packing Machine

Feature Of Core Filling/Inflating Snacks Machines:

Feature Of Core Filling/Inflating Snacks Machines:

①Versatility: The machine is capable of producing a wide variety of snack products, including core-filled and inflated snacks, with different shapes, sizes, and flavors.

②Efficiency: The machine is highly automated, which makes it faster and more efficient in producing snacks than manual processes. This helps to increase productivity and reduce labor costs.

③Precision: The machine is designed to produce snacks with a high degree of accuracy, consistency, and quality. This ensures that the snacks are uniform in shape, size, and filling quantity.

④Flexibility: The machine can be easily adjusted to accommodate different snack products, flavors, and production volumes.

⑤Hygiene and Safety: The machine is made of food-grade materials and is easy to clean and sanitize, which ensures that the snacks produced are safe for consumption.

⑥Energy-saving: The machine is designed to be energy-efficient, which helps to reduce operating costs and make it an environmentally friendly option.

⑦Durability: The machine is designed to be robust and durable, which means it can operate reliably over an extended period with minimal maintenance.

Overall, the core filling/inflating snacks making machine is a reliable and efficient piece of equipment that helps to streamline snack production processes and produce high-quality snacks for consumers.

Machine Photos Of Core Filling/Inflating Snacks Production Line:

Machines Materials: All the machines are made by stainless steel.

Parameter Of Core Filling/Inflating Snacks Machine:

|

Model |

Installed Power (KW) |

Power Consumption (kw) |

Capacity (kg/h) |

Dimension (m) |

|

LY65 processing line |

80kw |

55kw |

120-150kg/h |

21*1.2*2.2 |

|

LY70 processing line |

115kw |

95kw |

200-250kg/h |

23*1.5*2.2 |

|

LY85 processing line |

170kw |

140kw |

500-700kg/h |

28*3.5*2.2 |

|

LY90 processing line |

230kw |

164kw |

800-1000kg/h |

29*2.5*3.5 |

Applications Of Core Filling/Inflating Snacks Production Line:

The core filling/inflating snacks production line is a complete set of equipment that includes various machines and processes for producing a range of snacks. Here are some of the applications of the core filling/inflating snacks production line:

①Snack food manufacturing: The production line can be used to manufacture a variety of snack products, such as potato chips, corn curls, rice crackers, biscuits, and wafers, with different shapes, sizes, and fillings.

②Food industry: The core filling/inflating snacks production line is a crucial part of the food industry, as it can be used to produce snacks on a large scale, making it easier to meet market demands.

③Catering industry: The snacks produced by the production line can be served as part of catering services in various events such as weddings, parties, and conferences.

④Retail industry: The snacks produced by the production line can be sold in retail outlets, such as supermarkets, convenience stores, and vending machines.

⑤Export industry: The production line can be used to produce snacks for export to different countries, thereby expanding the market and generating revenue for the manufacturers.

Overall, the core filling/inflating snacks production line has numerous applications in the food industry and other related industries. It is an essential piece of equipment that helps to produce high-quality and delicious snacks that are popular with consumers around the world.