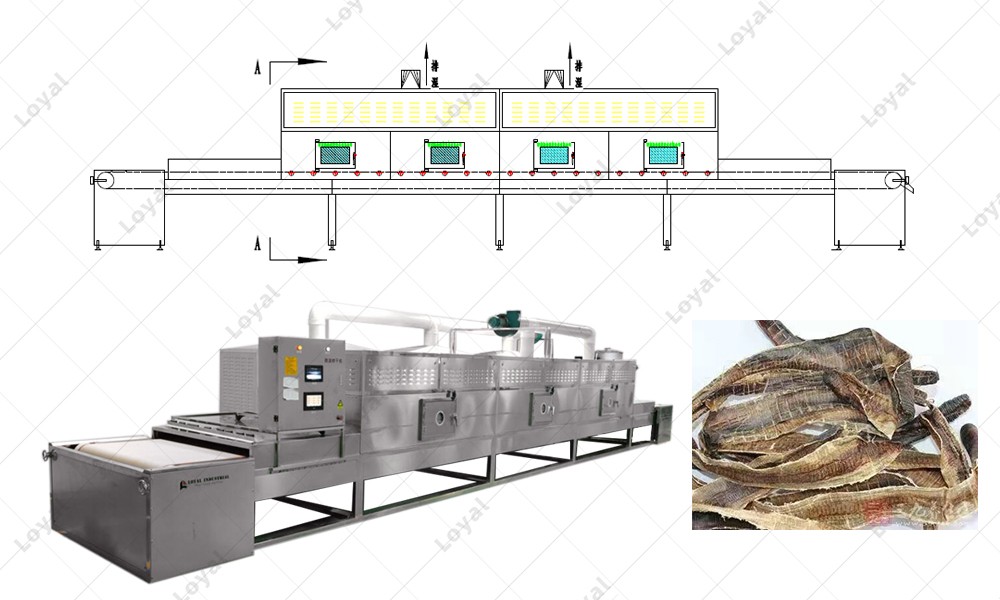

Earthworms Drying Microwave Oven

Description Of Earthworms Drying Oven

The earthworm dryer is a kind of equipment specially used for drying earthworms, which is used for various purposes such as scientific research, commercial breeding or fishing bait production. Ovens are usually cabinet units with a temperature control system to regulate the drying process. This type of oven is designed to dry earthworms at low temperatures, usually between 30-50°C, to preserve their quality, nutrition and texture. Ovens usually include several racks or trays to allow maximum airflow around the worms, which helps ensure even drying. The drying process usually takes a few hours to a few days, depending on the number of worms to be dried and the desired final moisture level. Depending on the intended use and application, worm drying ovens come in different sizes and designs. They are an essential tool for anyone who needs to dry earthworms on a large scale.

How To Dry The Earthworms

- Take fresh earthworms and wash them clean without dust or debris.

- Spread the worms on the grill or baking sheet, making sure they don't crowd or touch each other.

- Set the oven temperature between 30-50°C. This temperature range is suitable for drying earthworms without affecting the quality and nutritional content of earthworms.

- Carefully place the grill or pan filled with earthworms into the oven.

- Dry the worms for at least 12 hours or more depending on the size of the oven and the number of worms to be dried.

- Check the earthworms regularly during the drying process to ensure uniform drying.

- After the earthworms are completely dry, take them out of the oven and store them in an airtight container.

It is important to note that drying time may vary based on a number of factors, including the size of the oven, the type of worms being dried, ambient temperature and humidity level. Therefore, drying progress must be monitored frequently to ensure adequate drying of the earthworms.

Working Principle Of Industrial Microwave Earthworms Drying Oven

The industrial microwave earthworm drying oven uses microwaves to heat and dry earthworms quickly and efficiently. When the oven is turned on, the heat energy generated by the microwave penetrates deep into the body of the earthworm and quickly evaporates the water in the body. This process is called dielectric heating. The oven is designed so that the microwaves are evenly distributed throughout the oven, ensuring that all the worms are evenly heated and dried. The drying process is facilitated by the oven's temperature and humidity sensors, which monitor the ambient conditions inside the oven and adjust accordingly to ensure optimal drying results. Industrial Microwave Earthworm Drying Ovens are designed to dry earthworms quickly and efficiently while retaining their nutritional value and quality. The drying time of the oven is much shorter than other conventional drying methods, and the obtained earthworms are storage-resistant, free from moisture, and have a long shelf life. In general, the working principle of the oven is based on the controlled application of high-frequency microwaves to heat and dry earthworms quickly and efficiently without compromising their quality.

Microwave Earthworms Dryer's Advantage

|

Faster Drying Time |

Compared with other conventional drying methods (such as sun drying or oven drying), the industrial microwave earthworm dryer can dry earthworms in a relatively short time. This saves time and increases productivity. |

|

Uniform Drying |

The microwave earthworm dryer ensures that the earthworms are evenly heated, dried evenly, and have consistent texture and flavor. |

|

Guarantee Of Quality |

Microwave drying is used to minimize the loss of nutrients in earthworms, so as to ensure quality and prolong the shelf life. |

|

Energy Efficiency |

Microwave worm dryers use less energy to dry worms than other traditional drying methods. |

|

Large-Scale Drying |

The microwave worm dryer is designed for processing a large number of worms at one time, which is very suitable for commercial applications. |

|

Improve Food Safety |

The controlled drying process of the microwave earthworm dryer eliminates the risk of contamination or deterioration that may occur in traditional drying methods. |

|

Cost-Effectiveness |

Microwave earthworm dryer is a cost-effective method of earthworm drying. Compared with traditional methods, it uses less resources and has higher output of dried earthworms per unit input. |

To sum up, microwave worm dryer has many advantages compared with traditional drying methods, and it is a more efficient and effective way to produce high-quality worm dryer.

Earthworms Product Display

|

Earthworms For Soil Fertilization |

Earthworms are excellent soil conditioners because they help break down organic matter, improve soil aeration and drainage, and release nutrients necessary for plant growth. Earthworms are sold as live bait or as compost worms for horticultural and agricultural purposes. |

|

Vermicompost |

Vermicompost or vermicompost is a natural fertilizer produced by earthworms. Vermicompost is rich in essential nutrients, microbes and organic matter, making it an excellent soil amendment for plant growth. |

|

Earthworms For Animal Feed |

Earthworms are rich in protein and other essential nutrients needed for animal growth and development. Earthworms are used as a substitute for fishmeal or meat feed for animals such as fish, chickens and pigs. |

|

Earthworm Products For Human Consumption |

Earthworms are used as a food source in some cultures, especially in Asia. Some companies sell earthworm-based supplements in pill and powder form for human consumption. Earthworms are said to be rich in nutrients such as protein, iron and calcium that can enhance health. |

In conclusion, earthworms are a product with a wide range of uses, including soil fertilization, animal feed, and human consumption, and there are many earthworm products available in the market.