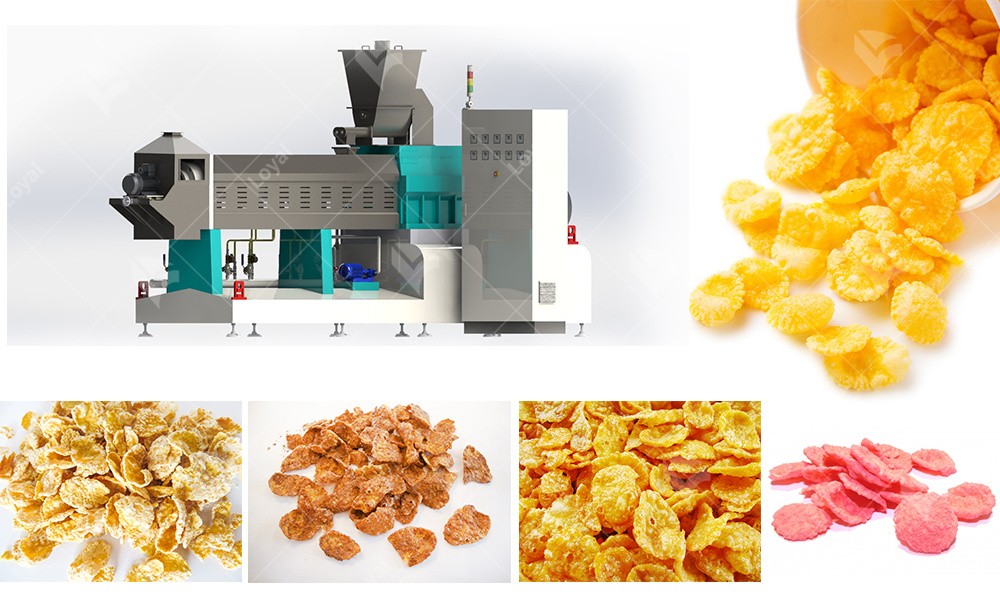

Corn Flakes Production Line

A corn flakes production line is a series of machines and equipment designed to produce corn flakes, a popular breakfast cereal made from corn.A typical corn flakes production line may include several machines, such as a corn cleaning machine, a soaking tank, a steam cooker, a flaking machine, a drying machine, a toasting machine, a sugar coating machine, and a packaging machine. The entire process is automated and can be controlled using a central computer system.Overall, a corn flakes production line is a sophisticated piece of equipment that requires skilled operators and quality control measures to ensure the finished product is of high quality and meets food safety standards.

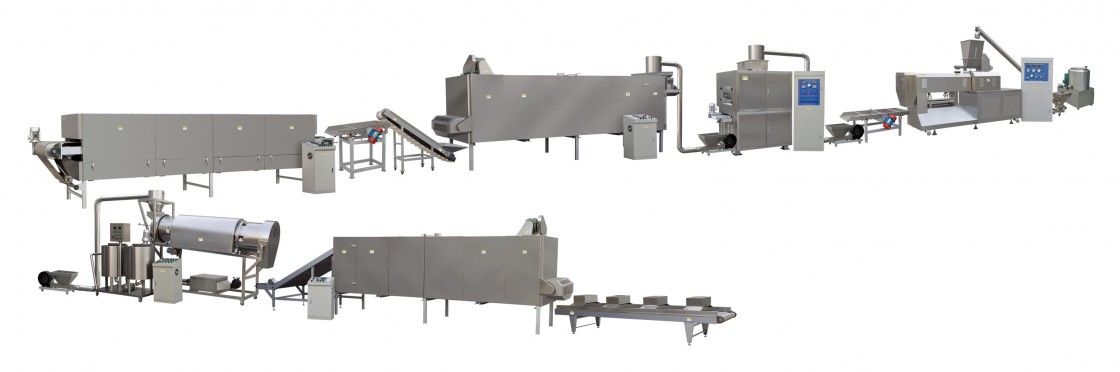

The Flowchart Of Corn Flakes Process Line

- Mixer --- 2. screw conveyer --- 3. Twin-screw extruder --- 4. Cooling Conveyor --- 5. Air conveyor --- 6. Flaking Machine --- 7. Air Conveyor --- 8. Pre-dryer --- 9. Hoister --- 10. Vibrate Feeder --- 11. Baking Machine --- 12. Sugar Sprayer --- 13. Multi-layer Oven --- 14. Cooling Conveyer --- 15. Packaging Machine

The Function Of Corn Flakes Process Line

- Cleaning and Conditioning: The corn grains are first cleaned to remove any impurities and then conditioned by soaking in water to soften them.

- Milling: The corn is then milled to produce a fine grit or meal.

- Cooking: The milled corn is cooked in a steam-jacketed cooker to form a dough.

- Flaking: The cooked dough is then fed through a flaking machine, which flattens it into thin flakes.

- Toasting and Drying: The flakes are then toasted and dried in a large oven to remove any moisture and give them a crispy texture.

- Coating: The flakes are coated with sugar, salt, vitamins, and other ingredients to enhance their flavor and nutritional value.

- Packaging: Finally, the corn flakes are packaged in boxes or bags and sealed for distribution.

The Parameter Of Corn Flakes Process Line

|

Model |

Installed Power (kw) |

Power Consumption (kw) |

Output

(kg/h) |

Size (L*W*H) (mm) |

|

LY65 |

140kw |

90kw |

120-150kg/h |

39000*1200*2200rnn |

|

LY70 |

160kw |

120kw |

180-220kg/h |

41000*1500*2200nm |

|

LY85 |

190kw |

140kw |

300-500kg/h |

43000* 3500*4300mm |

|

LY90 |

240kw |

190kw |

800-1000kg/h |

65000* 5000*4300mm |

The Advantage Of Corn Flakes Process Line

|

High Production Efficiency |

The corn flakes process line is a highly efficient system that can produce large quantities of corn flakes in a short amount of time. |

|

Customization |

The process line can be customized according to the specific requirements of the customer. It allows the production of a wide range of corn flakes with different shapes, sizes, and flavors. |

|

Cost-effective |

The corn flakes process line is a cost-effective solution for large-scale production of corn flakes. It requires fewer resources and labor compared to traditional methods of making corn flakes. |

|

Consistency |

The process line ensures consistency in the quality, texture, and taste of the corn flakes produced. |

|

Hygienic |

The process line is designed to maintain high levels of hygiene and cleanliness throughout the production process, ensuring the safety of the final product. |

|

Versatility |

The corn flakes process line can be used to produce a variety of other breakfast cereals, such as wheat flakes, oat flakes, and rice flakes. |