Automatic Deep-Fried Potato Chips Production Line

1.Introduction Of Automatic Fried Potato Chips Production Line

The new French fries/ potato chips production line with international level is developed and researched by our LOYAL company independently.The potato chips/French fries processing line is made of high quality304 stainless steel, and PLC electrical control system, with the high technical content, safety and efficiency, etc features. The bearings are all made of imported stainless steel, and the electrical parts etc.are made of imported brands, and the technology level is the leading one in China.

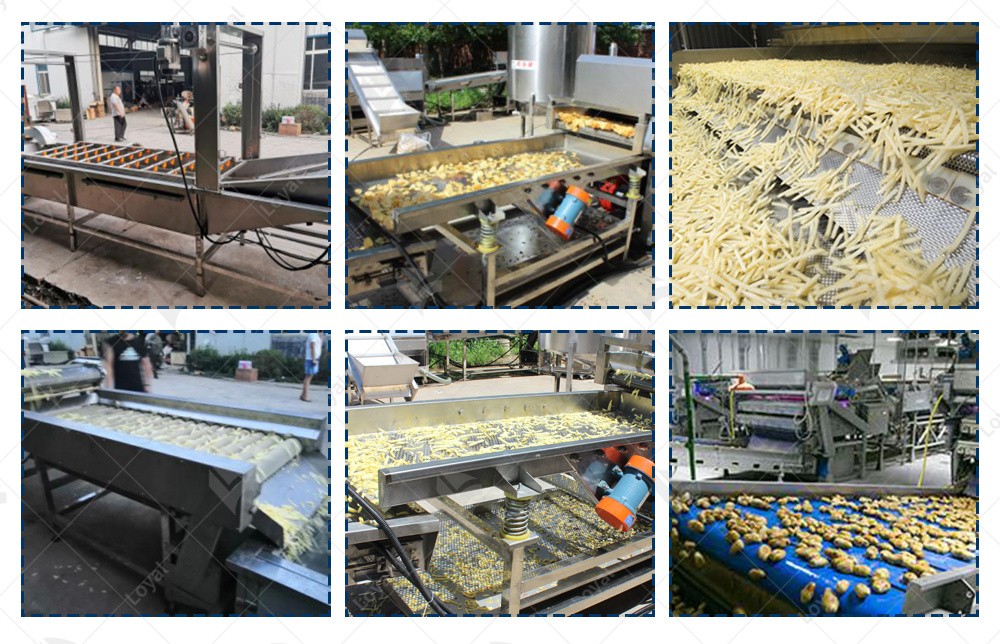

2.Automatic Deep-Fried Potato Chips Production Line’s Process Flow

Process flow:Water Bucket Sinking Stone Elevator→Washing&Peeling Machine → Picking Line→Hoist→Cutting Machine→ Bubble Rinsing Machine →Blanching Machine →Vibrating Water Removal Machine→Air-Cooling Line→Hoist→Frying Machine→ Vibratory De-oiling Machine→Hoist→ Seasoning System→ Packing Machine.

The whole machine line can also be adapted to produce Frozen French fries by adjusting the process.

3.High Quality Deep-Fried Potato Chips Production Line’s Equipment Composition

|

Washing And Peeling Machine |

A washing and peeling machine with a golden sand lining or a brush type washing and peeling machine, which can complete the work of washing and peeling at the same time.High efficiency and low loss. |

|

Cutting Machine |

Cut the potato into chips or strip type.The thickness of the chips and the size of the strips can be adjust.ed at will. |

|

Blanching Machine |

rinse the cut potato chips (strips) and protect the color. |

|

Dewatering Machine |

Dewatering by centrifugal force.De-oiling machine: centrifugal de-oiling machine,just fried potato chips (fries) for de-oiling, to overcome the high oil content of the chips (fries), greasy mouth defects. Improve the taste of potato chips (fries). |

|

Oil-Water Mixed Frying Machine |

This equipment is an advanced frying equipment. Due to the different proportions of water and oil, the water is at the bottom, and the oil is heated on the upper layer to make potato chips. The resulting residue is directly deposited in the water, and the oil does not emit black smoke, which greatly prolongs the service life of the oil and greatly reduces the cost. The oil temperature is precisely controlled, thus ensuring the quality and taste of potato chips and fries. After the work is completed, the water is released, and the residue will flow out with the water. |

|

Deoiler |

Centrifugal deoiler, which deoils freshly fried potato chips (strips), overcoming the defects of high oil content and greasy mouth of potato chips (strips).The taste of potato chips (strips) is improved. |

|

Automatic Seasoning Machine |

The drum type seasoning machine is made of stainless steel.The potato chips (strips) are evenly turned in the rotation of the drum, and the seasoning is added by sprinkling or spraying.Seasoned evenly and not brittle. |

|

Nitrogen Filling Packaging Machine |

When packaging, filling the packaging bag with nitrogen can effectively prevent potato chips (strips) from breaking and prolong the shelf life.Inflate, pack, and code at one time. |

4.Advantages Of Automatic Deep-Fried Potato Chips Production Line

The continuous frying line is highly automated. There are automatic and manual lifting system, unique product conveying system, slag removal system, heating system, oil circulation system, smoke exhaust system, electric control system, etc.

The main body of the machine is made of stainless steel; double mesh belt conveying food, mesh belt speed adjustable by frequency; automatic lifting system is convenient for workers to clean up the sanitary inside the machine; constant temperature continuous production ensures that the temperature and time of the fried food is consistent.

5.Applications Of Automatic Deep-Fried Potato Chips Production Line

Automatic deep-fried potato chips production line is suitable for medium and large-sized deep-fried food processing enterprises, and is widely used in the processing of fried foods such as meat pieces, fried chicken wings, meat products, pot pies, aquatic products, vegetables and pasta.