How To Make Wafer Biscuit Automatically?

Introduction Of Wafer Biscuit Making Machine:

A Wafer Biscuit Making Machine is a specialized piece of equipment that is used in the production of wafer biscuits. These machines are used to automate the entire process of wafer biscuit production, from mixing the dough to baking the biscuits and packaging them.Wafer Biscuit Making Machines are designed to produce a large volume of wafer biscuits in a short amount of time, and they are commonly used in large-scale commercial bakeries and production facilities.The use of a Wafer Biscuit Making Machine helps to streamline the production process, increase efficiency and productivity, and reduce the labor required to produce wafer biscuits.

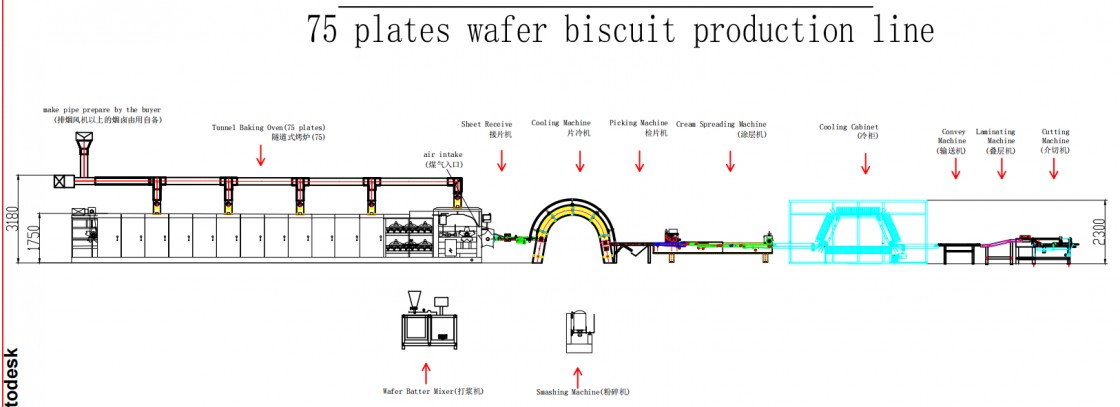

The Equipment Using In The Wafer Biscuit Making Machine:

1.Mixing tank: A tank used for mixing the batter ingredients, including flour, sugar, and water.

2.Batter pump: A pump used to transfer the batter from the mixing tank to the baking plates.

3.Baking plates: Metal plates with heating elements used to bake the wafer batter into thin, crispy wafers.

4.Cooling conveyor: A conveyor belt used to transfer the baked wafers to cool down before further processing.

5.Cream spreading machine: A machine used to spread cream or filling onto the wafer sheets.

6.Cutting machine: A machine used to cut the wafer sheets into individual pieces or shapes.

7.Packaging machine: A machine used to pack the finished wafer biscuits into boxes or bags.

Parameter Of Wafer Biscuit Making Machines:

|

Model |

27 |

33 |

39 |

45 |

51 |

65 |

75 |

100 |

|

Oven Length (Mm) |

6000 |

7150 |

8300 |

9450 |

10600 |

13300 |

15000 |

20000 |

|

Production Line Length (Mm) |

22000 |

23150 |

24300 |

25450 |

26600 |

29300 |

38500 |

44350 |

|

Oven Power (Kw) |

5.52 |

5.52 |

5.52 |

5.52 |

5.52 |

5.52 |

8.12 |

24 |

|

Consumption Of Liquefied Gas (Kg/h) |

13 |

15 |

19 |

23 |

27 |

32 |

45 |

50 |

|

Natural Gas Consumption (m³/h) |

16 |

21 |

25 |

30 |

35 |

45 |

58 |

67 |

|

Electric Heating Power (Kw) |

14 |

17 |

20 |

23 |

26 |

33 |

45 |

78.8 |

|

Output (Kg/h) |

90 |

110 |

130 |

150 |

170 |

215 |

300 |

780 |

Feature Of Wafer Biscuit Machines:

1. Versatility: Wafer Biscuit Making Machines are designed to produce a wide range of wafer biscuit varieties, shapes, and sizes.

2. Automated Operation: The machine is fully automated and requires minimal human intervention. All the processes, from mixing the dough to packaging the biscuits, are automated.

3. Energy Efficient: These machines are designed to be energy-efficient, consuming less electricity and reducing production costs.

4. High Production Capacity: Wafer Biscuit Making Machines can produce a large volume of biscuits in a short time, significantly increasing production capacity.

5. Easy to Clean: Wafer Biscuit Making Machines are easy to clean and maintain, with removable parts that can be easily washed and reassembled.

Applications Of Wafer Biscuit Making Production Line:

|

1 |

Confectionery Industry |

The Wafer Biscuit Making Production Line is widely used in the confectionery industry to produce wafer biscuits in different sizes, shapes, and flavors. |

|

2 |

Bakeries |

Large and small bakeries use wafer biscuit machines to produce a variety of wafer biscuits to cater to their customers' demands. |

|

3 |

Snack Food Industry |

Wafer Biscuits are a popular snack in the snack food industry. The Wafer Biscuit Making Production Line is used to produce wafer biscuits in bulk to cater to consumers' demands. |

|

4 |

Cafes and Coffee Shops |

Cafes and coffee shops use wafer biscuits as a complementary item to serve with coffee or other beverages. |

|

5 |

Hotel Industry |

Hotels use wafer biscuits as a part of their breakfast buffet or room service. |