How To Make Fried Potato Chips Automatically?

Introduction Of Fried Potato Chips Making Machine:

The fried potato chips making machine is a specialized machine designed for the commercial production of crispy and delicious potato chips. It is an automated machine that can perform various functions, including potato peeling, slicing, washing, frying, and packaging. The machine is made of high-quality stainless steel material, which ensures the durability of the machine and makes it easy to clean and maintain. The machine is also equipped with advanced technology, including temperature control, safety devices, and automatic oil filtration. With the fried potato chips making machine, high-quality and tasty potato chips can be produced in large quantities within a short period of time, making it ideal for commercial use.

The Fried Potato Chips Production Line Details :

|

Capacity |

100kg-2000kg |

|

Power Supply |

Based on 380V 50 Hz 3 phase. Customized according to your local power. |

|

Machine details |

1.Stainless steel,:201, 304, 316, on request |

|

Certificate |

CE,GOST,TUV,BV |

|

Raw Material |

Wheat flour, corn, rice, oat, etc. |

|

Products Color |

White, Yellow |

|

Products type |

Potato chips,french fries.etc. |

Flow Chart Of Commercial Fried Potato Chips Processing Line:

Feeding Material àWashing&PeelingàSorting Material àFeeding MaterialàCutting MachineàRinsing àBlanching MachineàDehydration MachineàFrying MachineàDe-Oiling Machineà Dryingà Flavoring àPacking Machine

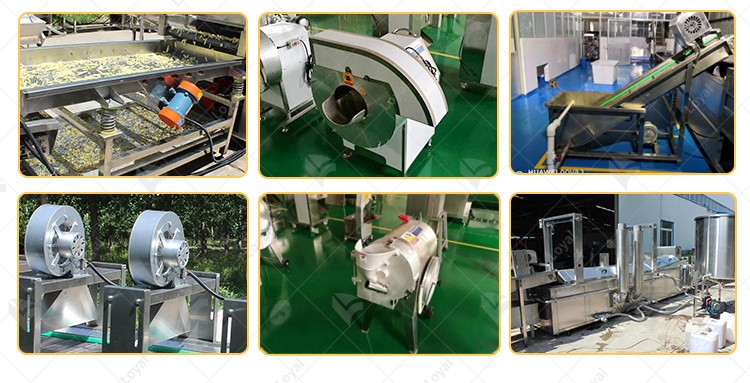

The Equipment Using In The Fried Potato Chips Making Machine:

Potato Washing And Peeling Machine→Potato Slicing Machine→Blanching Machine→De-Watering Machine→Fryer→De-Oiling Machine→Flavoring Machine→Packaging Machine

Feature Of Fried Potato Chips Machines:

1. Automated operation: The machine is fully automated, which makes it easy to operate and require minimal human intervention.

2. High production capacity: The machine can produce a large quantity of potato chips in a short period of time, which makes it ideal for commercial use.

3. Energy-efficient: The machine is designed to be energy-efficient, which means that it consumes less power and helps to reduce operating costs.

4. Easy to clean and maintain: The machine is made of high-quality stainless steel material, which makes it easy to clean and maintain.

Parameter Of Fried Potato Chips Machine:

|

Model |

semi20-30kg |

semi60kg |

semi150kg |

auto60kg |

auto150kg |

auto300kg |

|

Power |

40kw |

65kw |

104kw |

153kw |

224kw |

296kw |

|

Voltage |

220v/50hz |

380v/50hz |

380v/50hz |

380v/50hz |

380v/50hz |

380v/50hz |

|

Capacity |

20-30kg/h |

60kg/h |

150kg/h |

60kg/h |

150kg/h |

300kg/h |

|

Weight |

1260KG |

1780KG |

2780KG |

7800KG |

9800KG |

12000KG |

|

Size |

8.5*1*1.5m |

11*1.2*1.5m |

13*1.6*1.6m |

40*1.2*2.3m |

45*1.2*2.3m |

55*1.2*2.3m |

Applications Of Fried Potato Chips Production Line:

|

1 |

Snack food manufacturing |

The production line is ideal for manufacturing potato chips and other snack foods for retail sale, supermarkets, and convenience stores. |

|

2 |

Foodservice industry |

The production line is used by restaurants, cafes, and other foodservice establishments to produce freshly cooked potato chips on-site for their customers. |

|

3 |

Catering industry |

The production line is used by catering companies to provide large quantities of freshly cooked potato chips for events such as weddings, corporate functions, and festivals. |

|

4 |

Food processing industry |

The production line is used by food processing companies to manufacture potato chips and other snack foods for wholesale distribution to retailers and other businesses. |

|

5 |

Export |

The production line can be used to manufacture potato chips for export to other countries. |